The Requirements of Automotive Aluminum Sheet on Timeliness

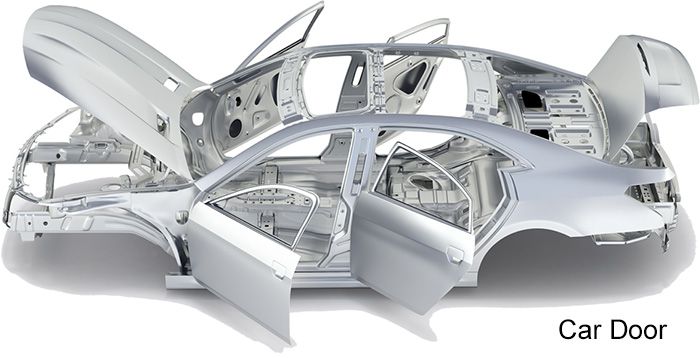

Amid the trend toward lightweight in automobiles, aluminum sheet, with its advantages of lightweight, high strength, and corrosion resistance, has become a key material in vehicle body manufacturing. The performance of automotive aluminum sheet is not static, and its "aging" directly impacts its processing performance and end-use performance.

Why is the aging of automotive aluminum sheet important?

The "aging" of automotive aluminum sheet essentially refers to the property of its internal microstructure (such as the precipitation of alloying elements and grain structure) to change over time at room temperature or a specific temperature, leading to changes in mechanical properties (strength, hardness, and elongation). This property is crucial for automotive manufacturing:

On the one hand, processing steps like stamping and bending for vehicle bodies place strict demands on the elongation and yield strength of aluminum sheet. If the aluminum sheet exceeds its optimal aging period, its hardness may increase and its elongation may decrease, leading to cracking during stamping. If it is under-aged, its strength may be too low, making the vehicle body susceptible to deformation after processing.

On the one hand, processing steps like stamping and bending for vehicle bodies place strict demands on the elongation and yield strength of aluminum sheet. If the aluminum sheet exceeds its optimal aging period, its hardness may increase and its elongation may decrease, leading to cracking during stamping. If it is under-aged, its strength may be too low, making the vehicle body susceptible to deformation after processing.

On the other hand, vehicles must withstand complex driving conditions such as bumps and collisions. The ultimate strength of aluminum sheet is directly related to the safety of the vehicle body. If the aging performance is not properly controlled, the aluminum sheet's performance may deteriorate or become unstable, potentially affecting the vehicle body's crash resistance and posing a safety hazard.

5754 aluminum sheet

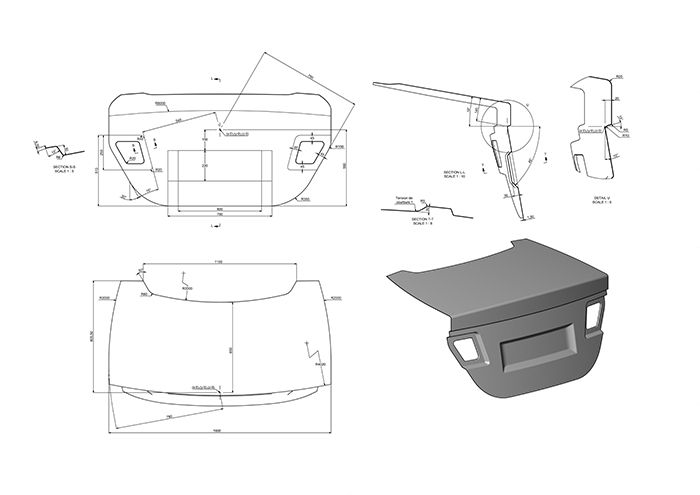

Aluminium en aw 5754 is a rust-resistant Al-Mg alloy with a magnesium content of approximately 2.6%-3.6%. Due to its excellent corrosion resistance, moderate strength, and good formability, it is often used in non-load-bearing or secondary load-bearing components such as door inner panels, trunk lid inner panels, and underbody panels.

Low Aging Sensitivity: 5754 aluminum sheet ages very slowly at room temperature (20-30°C), typically requiring several months or even over six months for noticeable changes in mechanical properties to occur (e.g., yield strength increases from approximately 110 MPa to 130 MPa, and elongation decreases from 25% to 20%). This means it has a longer "processing window," allowing automakers to avoid rushing to process the sheet after purchase and schedule production within a reasonable inventory period (generally recommended to be no more than six months).

Controllable Low-Temperature Aging: If accelerated performance stabilization is desired, low-temperature aging (e.g., 60-80°C for 4-6 hours) can be used. This shortens the aging cycle while preventing grain coarsening caused by high temperatures. However, it should be noted that prolonged exposure to high temperatures (e.g., workshop temperatures exceeding 40°C in summer) can accelerate natural aging, potentially leading to insufficient elongation during processing and the appearance of stamping cracks.

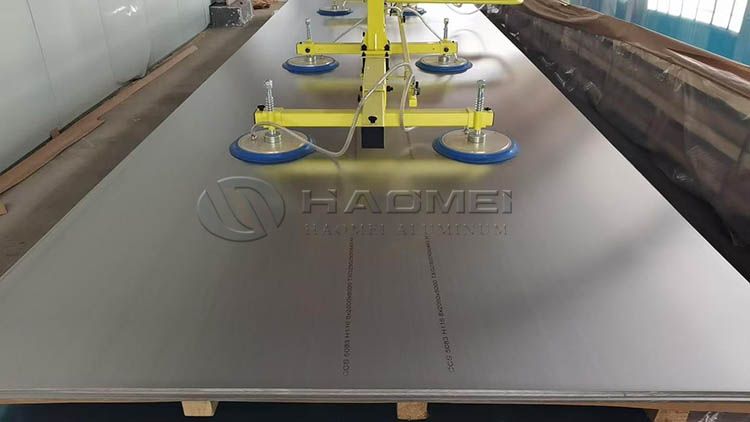

6016 aluminum sheet

Unlike 5754, 6016 aluminum sheet for sale is a heat-treatable, hardened Al-Mg-Si alloy containing magnesium (0.4%-0.8%) and silicon (0.8%-1.2%). Through solution treatment and artificial aging, it achieves high strength and excellent formability, making it the preferred material for load-bearing components such as automotive exterior panels (such as hood and roof panels) and pillars.

Fast natural aging: After solution treatment (530-550°C followed by rapid cooling), 6016 aluminum sheet ages extremely quickly at room temperature. The yield strength rises from 80 MPa to 140 MPa within 24 hours, stabilizing at 150-160 MPa after three days, while the elongation decreases from 30% to around 18%. This means its processing window is extremely short, typically requiring stamping to be completed within 48 hours after solution treatment. Otherwise, if the natural aging process is excessive, the yield strength exceeds 160 MPa and the elongation falls below 18%, resulting in a loss of formability and the stamping being scrapped.

Artificial aging requires precision: If processing time needs to be extended, a "low-temperature pre-aging" process (e.g., 120-140°C for 1-2 hours) can be used to slow down the natural aging process, extending the processing window to 7-10 days.

However, artificial aging parameters must be strictly controlled: Excessively high temperatures (above 150°C) will lead to "over-aging," resulting in coarse precipitation and a decrease in strength; excessively low temperatures (below 110°C) will not effectively inhibit natural aging, resulting in poor results.

Final aging determines performance: The ultimate performance of 6016 aluminum sheet relies on "artificial aging" to finalize its shape. After processing, it undergoes artificial aging at 170-180°C for 6-8 hours to allow magnesium and silicon to form a uniform Mg2Si precipitation phase. The ultimate yield strength reaches 180-200 MPa and the tensile strength reaches 260-280 MPa, meeting the load-bearing requirements of the vehicle body.

Insufficient aging time or temperature deviations will result in substandard strength, potentially making the vehicle body unable to withstand the impact of a collision. Excessive aging will lead to a decrease in plasticity, making the vehicle body susceptible to brittle fracture under stress.

Original Source:https://www.autoaluminumsheet.com/a/the-requirements-of-automotive-aluminum-sheet-on-timeliness.html

Tags: 5754 aluminum sheet ,

Prev:The Use of Al 5754 and 3003 in Automobile

Next:What Are Car Hoods Made of