What Is The Manufacturing Craft of Automotive Aluminum 6061 and 5083

6061 aluminum alloy, as a representative of heat-treatable alloys, has the core advantage of "controllable strength and toughness." By adding magnesium and silicon as main alloying elements, and after solution treatment and artificial aging, its tensile strength can reach over 310 MPa, while also possessing excellent machinability and weldability.

This "combination of rigidity and flexibility" makes it an ideal choice for automotive structural components. In the field of new energy vehicles, AA 6061 alloy is commonly used in battery pack frames, which must support the weight of hundreds of kilograms of batteries and withstand vibrations and impacts during driving. CNC-machined 6061 frames can achieve a 40% weight reduction compared to steel while meeting IP67 sealing requirements.

Furthermore, it is a common material for engine mounts and suspension system linkages. In traditional gasoline vehicles, anodized 6061 components can further enhance corrosion resistance.

5083 aluminum sheet, on the other hand, is a leader among rust-resistant aluminum alloys. With magnesium as the main alloying element (content reaching 4%), it belongs to the non-heat-treatable alloy category. Its core competitiveness lies in "extreme corrosion resistance" and "excellent formability."

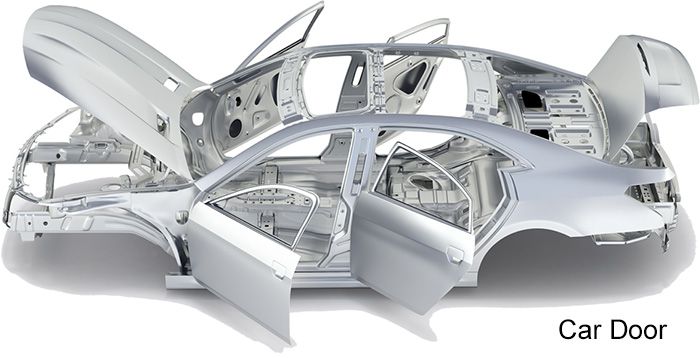

In marine climates or high-humidity environments, 5083 aluminum alloy exhibits significantly superior resistance to stress corrosion compared to ordinary aluminum alloys, and its elongation can exceed 20%, making it ideal for forming complex curved surfaces. This characteristic makes it highly sought after in the automotive body industry, particularly in components such as convertible body panels and SUV door panels.

For example, door panels of a high-end SUV brand, stamped from 5083 aluminum alloy, are not only 35% lighter than steel components, but also allow for complex reinforcing rib structures through adjustments to stamping parameters, enhancing collision safety. Simultaneously, 5083 is also commonly used in automotive fuel tanks and cooling system piping, its resistance to fuel corrosion effectively extending component lifespan.

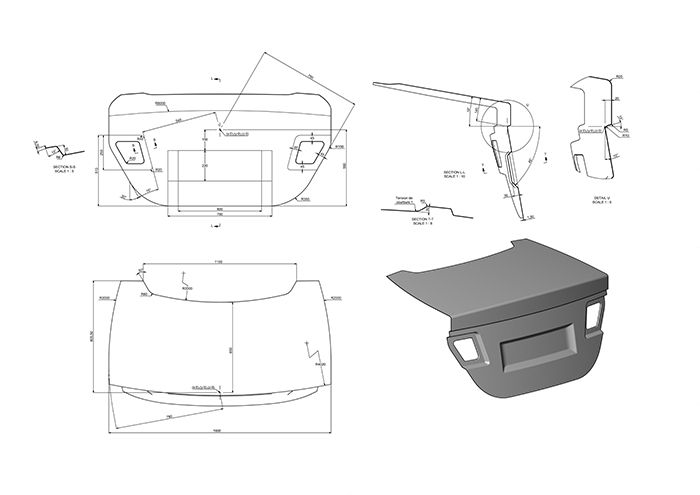

While the manufacturing processes of these two aluminum alloys share commonalities, precise matching of their properties is essential. The key to 6061 aluminum alloys lies in heat treatment control: ingots are heated to 530-550℃ for homogenization to eliminate compositional segregation; after rolling or extrusion, solution treatment is performed at 500-510℃, followed by rapid water cooling to room temperature, and finally aging at 170-180℃ for 6-8 hours to enhance strength through the precipitation of Mg₂Si strengthening phases.

The core of 5083 aluminum alloys is optimized rolling processes. Ingots require hot rolling at 400-450℃, with the reduction rate controlled at 30%-40%. During cold rolling, intermediate annealing (300-350℃) eliminates work hardening, ensuring stable formability of the final sheet. Argon arc welding is used during welding to prevent magnesium loss and performance degradation.

From structural components to body panels, 6061 and 5083 aluminum alloys, with their differentiated advantages, form the core material system for automotive lightweighting. As the automotive industry upgrades towards electrification and intelligence, the performance requirements for aluminum alloys will become more diverse, and these two classic alloys will continue to revitalize themselves through composition optimization and process innovation.

Haomei Aluminum is a big 6061 and 5083 aluminum sheet supplier. Welcome to tell us the specification you need directly.

Original Source:https://www.autoaluminumsheet.com/a/what-is-the-manufacturing-craft-of-automotive-aluminum-6061-and-5083.html

Tags: 5083 aluminum sheet ,

Prev:What Is 5052 Automotive Aluminum Used For

Next:5754 Aluminum Sheet For Medium-Strength Applications