5754 Aluminum Sheet For Medium-Strength Applications

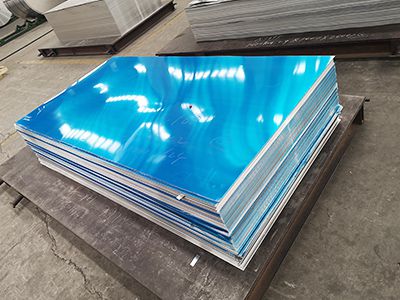

5754 aluminum sheet belongs to the Al-Mg series of rust-resistant aluminum alloys. The addition of magnesium ensures its tensile strength remains stable between 160-300 MPa. This strength range perfectly matches the "medium strength requirements" of many industrial and consumer sectors—able to withstand certain loads and pressures without increasing processing difficulty or costs due to excessive strength.

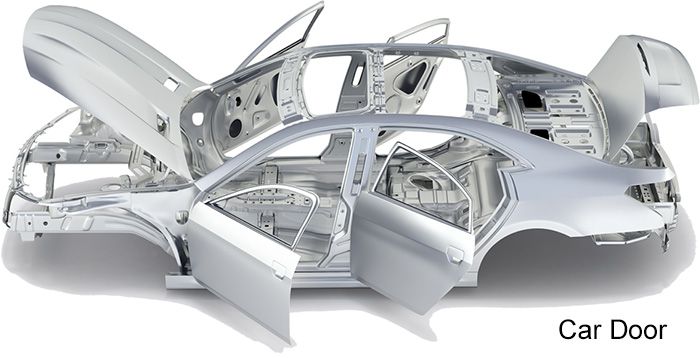

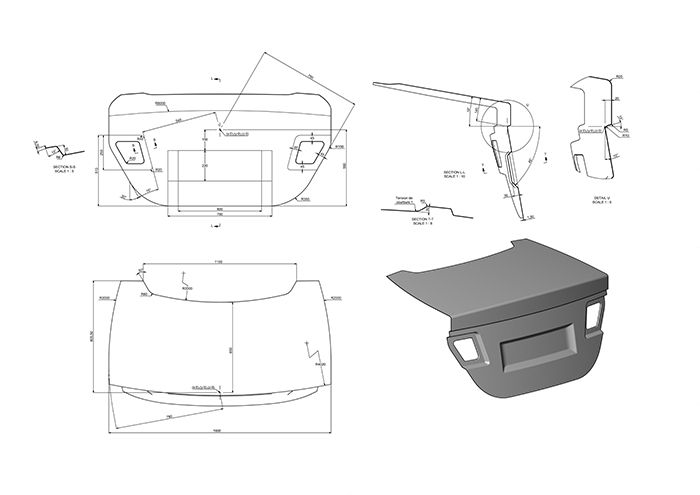

1. Automotive industry

With the trend towards lightweight automobiles, 5754 aluminum sheet has become an ideal choice for body panels and chassis components. Components such as body side panels and engine hood panels need to withstand wind resistance, vibration, and minor collisions during daily driving.

The moderate strength of 5754 ensures structural stability while reducing weight by more than 30% compared to steel, thus lowering fuel consumption. Furthermore, its corrosion resistance reduces rust caused by rainwater and road salt, extending vehicle lifespan.

Aluminium 5754 h111(not fully annealed) is an ideal choice, as its tensile strength of 180-220 MPa and good machinability offer a balanced advantage, easily handling simple processing operations.

2. Shipbuilding and marine engineering

The high salinity and humidity of the marine environment place stringent demands on the corrosion resistance of materials, a requirement perfectly met by the rust-resistant properties of 5754 aluminum sheet.

Ship deck linings, cabin interior trim, and auxiliary structural components of offshore platforms do not require extreme heavy loads but need long-term resistance to seawater corrosion. The moderate strength of 5754 is sufficient for daily use, while avoiding the high costs associated with using highly corrosion-resistant alloys.

3. Pressure Vessels

In the field of small pressure vessels, such as protective covers for household liquefied petroleum gas cylinders and drinking water storage tanks, 5754 aluminum sheet also performs excellently. These containers need to withstand a certain internal pressure while ensuring safe use and resistance to deformation. The strength of 5754 meets the design pressure requirements, and its good weldability facilitates processing and shaping. Furthermore, its non-toxic and odorless properties comply with food-grade and civilian safety standards.

For pressure vessel components operating in slightly more complex environments (such as minor vibrations or intermittent pressure fluctuations), the H22 state (work-hardened state) is a better solution. With moderate work hardening, this state achieves a tensile strength of 210-250 MPa, falling between H111 and H112.

Aluminum 5754 h22 properties offers superior pressure resistance compared to H111 while retaining better bending and edge-rolling performance than H112, meeting the moderate processing requirements during component forming. Its excellent corrosion resistance also prevents raw material corrosion.

4. Architectural Decoration

For exterior curtain wall panels, interior ceiling decorative panels, and some small structural components, the material requirements are "sufficient strength, aesthetic appeal, and durability." 5754 aluminum sheets can achieve rich colors and textures through anodizing and spraying processes.

Their moderate strength also resists deformation caused by outdoor wind loads and temperature changes, preventing cracking and bulging on the decorative surface, thus combining practicality and aesthetics.

Original Source:https://www.autoaluminumsheet.com/a/5754-aluminum-sheet-for-medium-strength-applications.html

Tags: 5754 aluminum sheet ,

Prev:What Is The Manufacturing Craft of Automotive Aluminum 6061 and 5083

Next:Which Vehicles Use A Lot of Aluminum