What is Automotive Industry Aluminum

In recent years, with the development of the automobile industry and the aviation industry, people have put forward higher requirements for the performance of aluminum alloys. The strength of aluminum alloys can be improved through appropriate component design, precise control of the strengthening phase in the alloy, and optimization of the heat treatment process system. 7075 alloy can have its properties improved through a proper heat treatment regime.

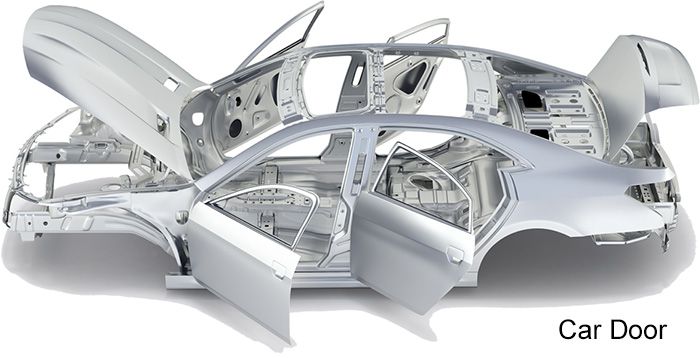

The automotive aluminum sheets have lower plasticity than steel plates, making it difficult to form parts with complex shapes. In particular, high-strength aluminum alloys are prone to problems such as cracking and springback.

In order to solve the problem of aluminum alloy forming, the industry has developed a hot forming process, which heats the aluminum alloy plate to a certain temperature to significantly improve its plasticity, thereby manufacturing parts with complex shapes. Aluminum alloy plates suitable for hot forming include 5754, 5083, 5182, 6111, 7075,etc.

The tensile strength of 7075 aluminum alloy is 560MPa, which is no lower than the strength of the steel. For the same weight of steel and aluminum, aluminum is larger and can increase structural strength without increasing weight.

Moreover, most of the current aluminum car bodies are welded with thick-walled forged aluminum beams, which have more advantages than stamped thin steel in terms of structural strength and stiffness, and the overall stability of the mechanism is better.

5xxx aluminum alloy is an aluminum alloy that cannot be strengthened by heat treatment. It has good corrosion resistance and welding performance. However, it may produce Lüders lines and delayed yielding during processing deformation in the annealed state. Therefore, it is mainly used for the inner panels. The more commonly used alloys are 5052 and 5083 aluminum plate.

The car's suspension swing arm and other bottom guard parts also use more aluminum alloys. The aluminum alloys used in this part include 5083 aluminum alloy, 5754 aluminum alloy, 6061 aluminum alloy, etc.

5xxx aluminum alloy is the most commonly used deformed aluminum alloy in wheel forging, mainly including: 5052-O, 5154-O, 5454-O, 5083-O, 5086-O. 5xxx forged aluminum alloy wheels have high corrosion resistance and are suitable for manufacturing the wheels that work in extreme environments. Welcome to leave message below to inquire 5083 aluminum plate price.

Original Source:https://www.autoaluminumsheet.com/a/what-is-automotive-industry-aluminum.html

Tags: automotive aluminum sheet ,

Next:What Is Aluminum Used for in Cars