5454 and 5052 Aluminum for Bus

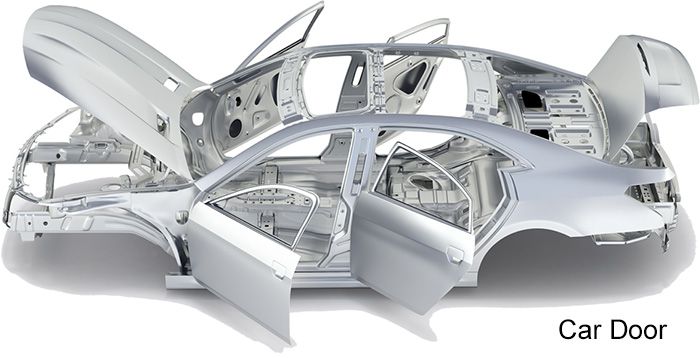

As core members of the aluminum-magnesium alloy family, 5052 and 5454 aluminum sheets are preferred materials for automotive manufacturing due to their lightweight and corrosion resistance. However, their performance focuses differ significantly:

5052 aluminum alloy: With a magnesium content of 2.2%-2.8% and a tensile strength of 170-305 MPa, it excels in balanced performance. Its key advantages lie in its excellent formability, weldability, and corrosion resistance, particularly its seawater resistance and fatigue resistance, while offering relatively manageable processing costs.

5454 alloy: The magnesium content is increased to 2.4%-3.0%, and elements such as manganese and chromium are added. Its tensile strength is ≥215 MPa, approximately 20% higher than 5052. Its core advantage is its superior corrosion resistance in harsh environments compared to 5154 alloy. It also exhibits outstanding stability in salt spray and humid conditions, while maintaining excellent processing and weldability.

5052 aluminum sheet

In bus manufacturing, 5052 aluminum sheet is one of the most widely used 5-series alloys due to its balanced performance. It is primarily used in three core components:

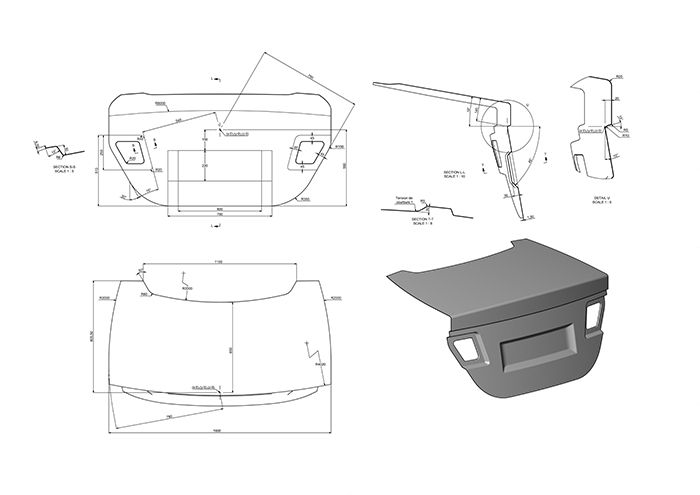

Bus body panel: It must simultaneously meet lightweight, flat, and weather-resistant requirements. 5052-H32 aluminum sheet (1.5-2.0mm thick) is the mainstream choice. Its surface flatness requirements are stringent—warpage exceeding 30mm within a 1000mm range is prohibited. Its excellent formability allows it to adapt to complex curved designs, and its oxide film also resists rain and snow erosion.

Luggage compartment components: 5052 aluminum sheet is commonly used for luggage compartment panels and cabin frames. Its moderate strength is sufficient to support luggage loads, and its lightweight properties reduce vehicle weight, indirectly improving range.

Anti-slip flooring: 5052 aluminum tread plate is the preferred choice for cabin flooring. Its patterned structure provides reliable anti-slip properties, while its corrosion resistance prevents rust from prolonged contact with shoe stains and cleaning fluids. Its weight is only one-third that of traditional steel sheet, reducing chassis load.

5052 aluminum is also used in fluid-carrying components such as bus fuel tanks and fuel pipes. Its weldability ensures the tank's airtightness, while its corrosion resistance extends its service life to over 10 years.

5454 aluminum sheet

Structural load-bearing components: Core structural components such as frame crossmembers and chassis supports require extremely high strength. 5454 medium plate (10-450mm thickness) is an ideal material due to its 20% strength advantage.

Special-purpose tanks: For specialized buses equipped with emergency fluid storage tanks and small fuel tanks (such as airport shuttles), 5454 aluminum sheet is the preferred material. Its corrosion resistance plays an important role in tank applications. Compared to traditional steel, 5454 extends the corrosion life of tanks from 6 years to 15 years, while reducing weight by 40%, meeting the "long life + lightweight" demand.

Wheels and suspension components: Bus wheels must withstand the weight of the entire vehicle and road impacts, making the high strength and wear resistance of 5454 aluminum sheet a perfect fit. Welcome to inquire 5454 and 5052 aluminum for bus from us.

Original Source:https://www.autoaluminumsheet.com/a/5454-and-5052-aluminum-for-bus.html

Tags: automotive aluminum sheet ,

Prev:What Are 6061 Car Aluminum Properties

Next:What Are Alloys of Aluminum Car Frame