What Are Alloys of Aluminum Car Frame

As the "skeleton" of a vehicle, the chassis must simultaneously fulfill multiple responsibilities: supporting the vehicle's weight, transmitting power and torque, absorbing collision energy, and maintaining structural stability under complex road conditions.

This places stringent demands on the performance of aluminum alloys—they must be strong enough to withstand impacts, possess a certain degree of formability to adapt to complex chassis structures, and also balance cost and ease of subsequent maintenance.

Choosing the wrong alloy can lead to excessive chassis weight and increased fuel consumption, or even breakage in a collision, threatening the safety of passengers. Therefore, alloy selection is an indispensable "preliminary hurdle" in chassis design.

Mainstream aluminum alloy series

1. 5 Series aluminum alloy

5-series aluminum alloys use magnesium as the main alloying element (containing 3%-5% magnesium). Their core advantages are good formability, strong corrosion resistance, and significantly improved strength through cold working, while remaining relatively affordable. However, their room temperature strength is moderate, and their high-temperature performance is poor; prolonged use in environments above 120°C can lead to strength degradation.

In car frame, 5-series aluminum alloys are more suitable for non-load-bearing or secondary load-bearing components, such as decorative body panels and lightly stressed connecting brackets. These components do not require high strength but need good bending and stamping properties, while also resisting corrosion from rainwater and road salt. The characteristics of 5-series alloys perfectly meet these requirements.

2. 6 Series aluminum alloy

6-series aluminum alloys, primarily composed of magnesium and silicon (0.4%-1.4% magnesium, 0.2%-1.2% silicon), achieve a balance between strength and toughness through heat treatment (T6 temper). Their tensile strength reaches 270-310 MPa, far exceeding that of 5-series alloys, while retaining good formability and weldability, and their corrosion resistance meets the requirements for automotive outdoor use. Due to its versatility, 6-series aluminum alloys have become the mainstream choice for automotive frames, widely used in core load-bearing components such as longitudinal beams, crossbeams, and pillars.

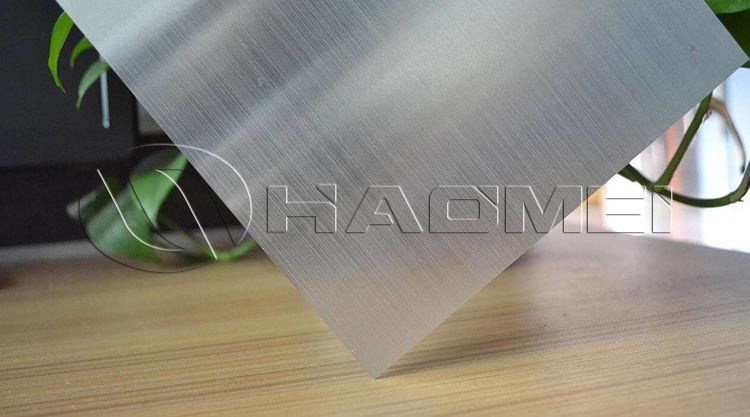

6061 sheet , with its excellent stamping and weldability, has become the preferred choice for non-core load-bearing but complex-shaped components in vehicle frames. Its thickness selection is highly dependent on the application scenario, ranging from 3mm thin sheets to 12mm medium-thick sheets, covering multiple sub-sections of the frame.

3. 7-Series aluminum alloys

7-series aluminum alloys, with zinc as the primary alloying element (4.0%-5.0%), supplemented with magnesium and copper, are currently the strongest civilian-grade aluminum alloy series, boasting tensile strengths exceeding 500 MPa, comparable to some low-carbon steels. However, its disadvantages are also significant: poor formability (difficult to perform complex bending), high welding difficulty (prone to stress corrosion after welding), and a cost 1.5-2 times that of 6-series.

Therefore, the application of 7-series aluminum alloys in automotive frames is relatively narrow, limited to scenarios with extreme strength requirements, such as key nodes in the frames of high-performance sports cars and load-bearing crossbeams in heavy commercial vehicles. Ordinary family cars rarely use 7-series aluminum alloys for their frames due to cost and molding requirements.

The stress characteristics of car frames vary greatly across different car models: family sedans prioritize comfort, requiring a certain degree of resilience in their frames to absorb road vibrations; new energy vehicles, due to the battery pack, need to withstand greater static weight, demanding higher strength; high-performance sports cars require extreme rigidity to enhance handling.

For example, the longitudinal beams of the chassis of new energy vehicles need to withstand the long-term pressure of the battery pack (weighing up to 300-500kg), in which case 6082-T6 aluminum alloy (tensile strength 310MPa) is more suitable than the 5 Series; while the "roll cage" of a sports car chassis needs to withstand the huge impact force during a collision, and 7075 t6 alloy (tensile strength 570MPa) is the better solution.

Original Source:https://www.autoaluminumsheet.com/a/what-are-alloys-of-aluminum-car-frame.html

Tags: 6061 aluminum sheet ,

Prev:5454 and 5052 Aluminum for Bus

Next:What Are Car Exteriors Made of?