What Are Car Exteriors Made of?

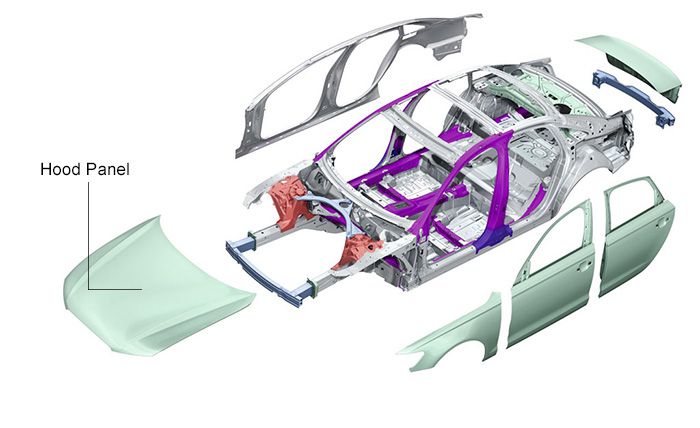

In today's automotive manufacturing industry, aluminum alloys have become a core material replacing steel for exterior construction. Compared to traditional steel, aluminum alloys can achieve weight reductions of over 30%, directly improving fuel economy and driving range, while also offering advantages in corrosion resistance and recyclability.

6000 series aluminium sheet uses magnesium (0.8%-1.5%) and silicon (0.3%-0.6%) as core alloying elements. These two elements form a Mg₂Si strengthening phase at high temperatures. After heat treatments such as T4 (solution treatment + natural aging) and T6 (solution treatment + artificial aging), nanoscale particles precipitate, significantly enhancing the material's strength.

This "heat-treatable strengthening" characteristic distinguishes it from 5-series aluminum alloys, which primarily rely on work hardening, allowing for a better balance between lightweight and strength.

Key Characteristics for Car Exteriors

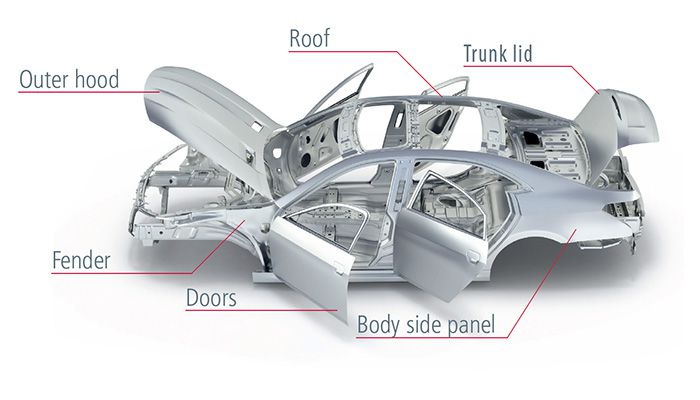

Balancing strength and formability: 6-series aluminum alloys have tensile strengths of 200-500 MPa, with 6061-t6 aluminum grade reaching a remarkable 310 MPa, meeting the impact resistance requirements of body panels. Simultaneously, excellent cold-working formability allows for the creation of complex curved surfaces such as hoods and fenders.

Excellent corrosion resistance: It exhibits no tendency for stress corrosion cracking and maintains good corrosion resistance even at high temperatures, significantly extending the lifespan of the car body against rain, snow, and road salt.

Good welding performance: It is compatible with both GTA-W and GMA-W welding processes, and most of the strength can be restored after welding treatment. They also have high surface smoothness after anodizing, with grades such as 6063 even achieving a mirror finish, suitable for automotive trim parts.

6056 aluminum alloy

EN AW-6056 is an Al-Mg-Si-Cu multi-element alloy. The addition of copper to the basic magnesium and silicon composition creates a more stable and strengthened structure. Compared to the commonly used 6061, its strength is increased by 15%; and compared to high-strength alloys like 2024 and 7075, its weldability and corrosion resistance are superior.

Its key performance parameters:

Thickness ranges from 0.8-3.5mm, adapting to the shell requirements of different parts.

After T4 aging treatment, it not only has excellent formability but also outstanding paint hardening ability, with a yield strength increase exceeding 80N/mm² after baking. With outstanding resistance to salt spray corrosion, it can easily withstand complex outdoor conditions such as rain and snow.

Currently, 6056 aluminum is widely used in the body shells of two types of vehicles: Passenger cars: Used for exterior body panels such as hoods and fenders, reducing weight by 20%-40% while ensuring energy absorption capacity during collisions;

Commercial vehicles and high-end models: Due to its strong fatigue resistance, it is also used in truck chassis shells and battery box frames for new energy vehicles, adapting to the needs of high load and long range.

Original Source:https://www.autoaluminumsheet.com/a/what-are-car-exteriors-made-of.html

Tags: 6056 aluminum alloy ,

Prev:What Are Alloys of Aluminum Car Frame

Next:5754 and 7075 Aluminum Sheet for Automobile