6111 Automotive Aluminum for Structural Parts

What Is 6111 Aluminum

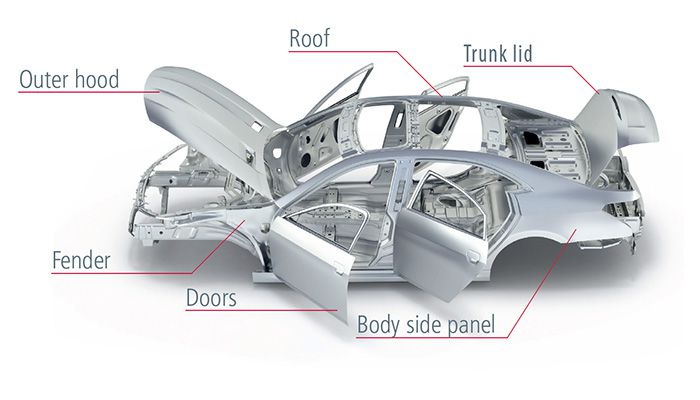

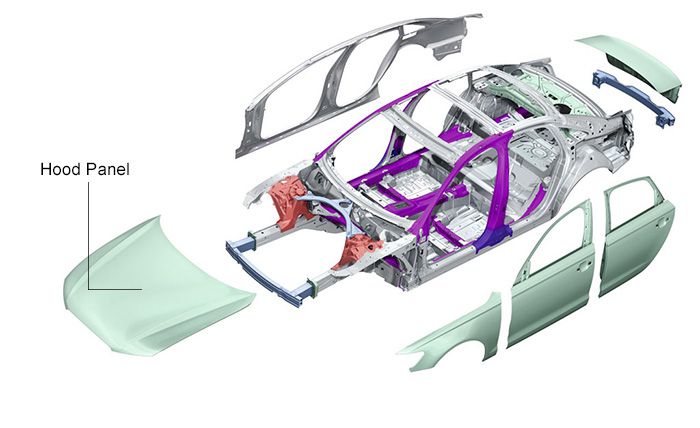

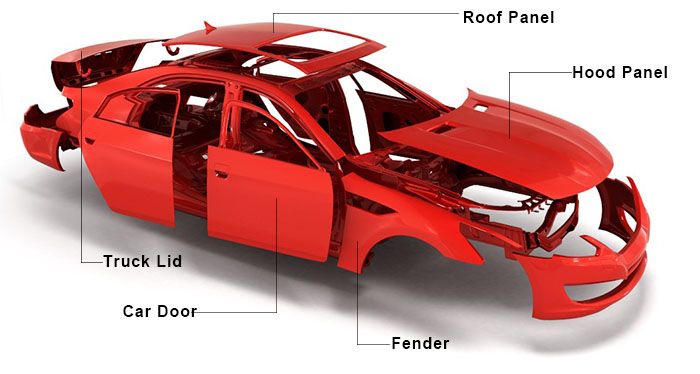

In recent years, the share of automotive steel has been declining.  Compared with steel, automotive aluminum features low density, higher specific strength and specific rigidity, good elasticity, good impact resistance, and quite high recycling rate.

Compared with steel, automotive aluminum features low density, higher specific strength and specific rigidity, good elasticity, good impact resistance, and quite high recycling rate.

6111 aluminum is a strengthened Al -Mg -Si -Cu alloy, having similar properties to 6061 aluminum plate. After casting and rolling, it is finally cold rolled to 1.55 mm. 6111 aluminum plate has the characteristics of impact resistance, moderate strength, good weldability, etc., and is widely used in auto parts, mechanical parts, precision machined parts, automotive structural parts and other fields.

It is favored by European and American countries because of its highest strength, thus achieving a more significant lightweight effect. At present, North American auto companies mainly use 6111 and 6022 aluminum alloy. European automobile companies mainly use 6016 aluminum sheet. Japanese car manufacturers mainly use 6016 and 6022 aluminum alloys, but also use some 6111 aluminum.

Specification of 6111 Aluminum Plate

Chemical Composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Standard(wt%) |

6111 | 0.6-1.1 | 0.40 | 0.5-0.9 | 0.1-0.45 | 0.50-1.0 | 0.10 | 0.15 | 0.10 | GB |

Mechanical Properties

Alloy | Temper | Tensile strength Rm(Mpa) | Yield strength Rp0.2(Mpa) | Elongation at Break A50(%) |

6111 | T4P | ≥250 | 115-170 | ≥20 |

Size

Alloy | Temper | Thickness | Width |

6111 | T4 | 0.8-3.5 | 1200-2650 |

The Production Process of 6111 Aluminum Sheet

This processing method is for improving the stamping formability of 6111 aluminum, including the following steps:

1. After the 6111 alloy ingot produced by semi-continuous casting is heat-treated at 220°C~425°C for 8h~15h, then it is rapidly heated to 550°C for 24h for regular homogenization treatment.

2. After the ingot is cut and milled, it is reheated to 440°C~450°C for hot rolling. The hot rolling adopts a horizontal and vertical alternate method. The total rolling deformation exceeds 85%, the final rolling temperature is >300℃, and the final thickness of the hot-rolled plate is 6mm.

3. After hot rolling, it is at 420℃~430℃ for 1h~2h, then after intermediate annealing treatment, it is then cold rolled to 0.8mm.

4. After the cold-rolled sheet is quenched by solution and water at 550℃ for 7 minutes, it should be parked at room temperature for 1min~48h.

5. It will undergo pre-aging treatment in the drying box, the temperature is 150℃-220℃, and the time is 4min-15min.

6. After being kept at room temperature for more than 2 weeks, it is in T4P temper.

Original Source:https://www.autoaluminumsheet.com/product/6111-automotive-aluminum-for-structural-parts.html

Tags: 6111 aluminum , automotive aluminum , 6111 aluminum plate ,