Application of 6111 and 6101 in Automobiles

6111 aluminum plate

6111 aluminum alloy belongs to the 6-series alloy family, based on the Al-Mg-Si alloy system. Its meticulously balanced chemical composition imparts a range of exceptional properties.

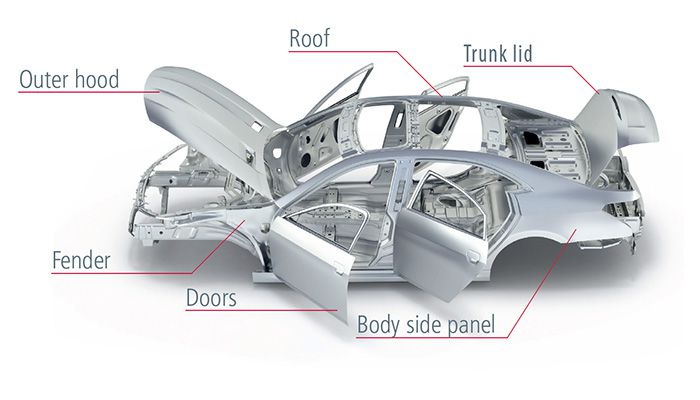

Automobile body panels: Exterior panels such as hoods, doors, and trunk lids place high demands on formability, surface quality, and strength. AA6111 boasts an elongation of 20-23%, far exceeding that of ordinary steel (15-20%). It can easily be stamped into complex curved surfaces, meeting the streamlined design requirements of modern vehicles.

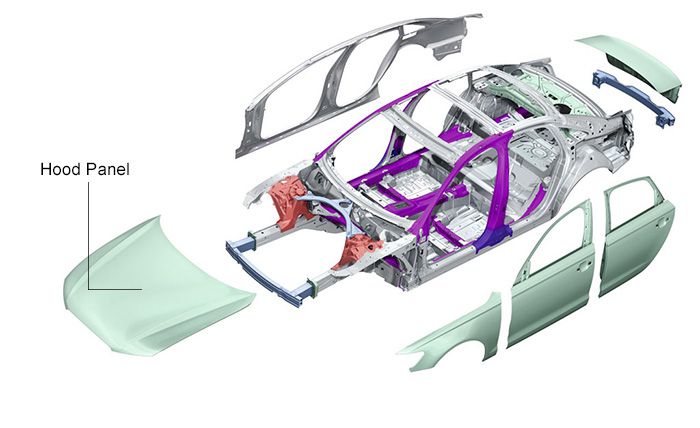

For example, a well-known automotive brand uses 6111 aluminum alloy for its hood panels. Its low springback (approximately 3-5° springback angle after stamping) effectively reduces dimensional deviation and ensures assembly accuracy. Furthermore, its smooth surface, free of orange peel marks after painting, and its natural oxide film imparts excellent corrosion resistance, preventing rust over time and enhancing vehicle aesthetics and durability.

Automobile structural components: 6111 aluminum alloy also demonstrates its strengths in the field of structural components. Through the aluminum hot forming (HFQ) process, AA6111 alloy can be used to manufacture complex structural components such as integrated door rings. The door ring serves as the central element of the exterior structure, integrating components such as the A-pillar, B-pillar, and sidewalls.

After HFQ processing, 6111 alloy achieves strengths ranging from Rp 0.2 to 360 MPa/Rm to 410 MPa, with a uniform elongation of Ag to 9-10%. This achieves significant lightweighting while maintaining structural strength and safety.

For example, a premium electric car features an integrated door ring made of 6111 alloy, weighing less than 9 kg. The additional B-pillar insert weighs 2.8 kg, significantly reducing vehicle weight compared to conventional materials, improving vehicle handling and fuel economy.

6101 aluminum sheet

6101 aluminum plate is also based on an Al-Mg-Si core system. By precisely controlling the magnesium (0.35% - 0.80%) and silicon (0.30% - 0.70%) content to form a Mg₂Si strengthening phase, and employing specialized heat treatment processes such as T63, it achieves a delicate balance of strength and conductivity. Amid the booming development of new energy vehicles, 6101 aluminum alloy is playing a revolutionary role in conductive systems.

Battery System Applications: In the conductive systems of new energy vehicle battery packs, 6101 aluminum alloy is an ideal lightweight alternative to copper and copper alloys. Its conductivity is stable at 55% IACS (International Annealed Copper Standard), far exceeding that of common aluminum alloys (such as 6061-T6, which has a conductivity of approximately 40% IACS), effectively reducing electrical resistance and improving battery charge and discharge efficiency.

Furthermore, with a density of only 2.7g/cm³ and a tensile strength comparable to copper wire, it is approximately 50% lighter, meeting the weight reduction needs of new energy vehicles. For example, the Tesla Model X uses 6101 aluminum alloy plate for its BUSBAR conductors, leveraging its high conductivity, high strength, and lightweight properties to optimize battery system performance and increase vehicle range.

Charging Facility Applications: With the advancement of fast-charging technology, performance requirements for charging pile busbar conductors are increasing. 6101-T63 aluminum busbars, with their high conductivity, excellent weldability (weld strength can reach over 90% of the parent metal), and superior corrosion resistance, are an excellent choice for charging pile busbar conductors.

Replacing copper busbars with 6101-T63 aluminum busbars can reduce system costs by over 30%, while meeting the high-current transmission requirements of fast charging and improving charging efficiency. For example, Tesla Superchargers use 6101-T63 aluminum busbars as busbar conductors, reducing system costs by 28% and increasing charging efficiency by 15%, driving the rapid development of new energy vehicle charging infrastructure.

Comparison: Differences in Performance and Applications Complement Each Other

6111 and 6101 aluminum alloys differ in performance and application, forming a complementary relationship. 6111 aluminum alloy is primarily used in vehicle body structures and panels, excelling in formability, strength, and corrosion resistance, providing a solid framework and aesthetically pleasing exterior.

6101 aluminum alloy, on the other hand, is specifically designed for the electrical conductivity systems of new energy vehicles, ensuring power transmission and storage with its high conductivity, lightweight design, and excellent overall performance. In actual automotive manufacturing, automakers will strategically select these two aluminum alloys based on the functional requirements of different components, leveraging their respective strengths to optimize overall vehicle performance.

Original Source:https://www.autoaluminumsheet.com/a/application-of-6111-and-6101-in-automobiles.html

Tags: 6111 aluminum plate ,

Prev:AA6016 6111 Aluminum Alloy

Next:Aluminium in Car Interior