AA6016 for ABS Outer Panel

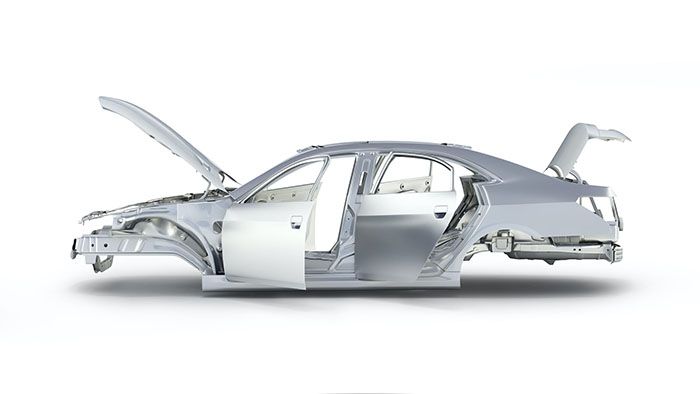

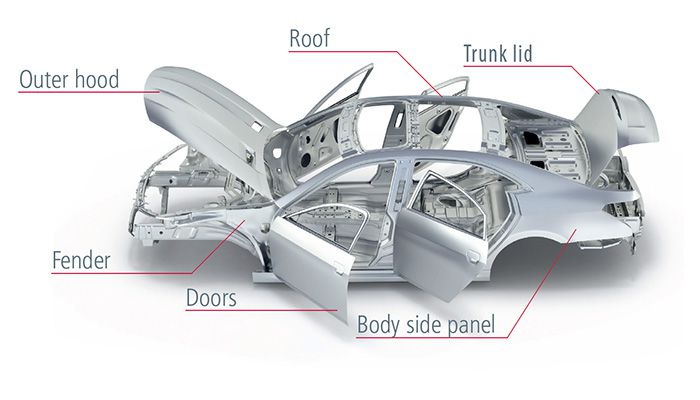

ABS is divided into two types: inner panel and outer panel. The performance requirements of the outer panel are high, and the production is difficult. Typical alloys of ABS aluminum sheet are 2002-T4, 21187-T4, 2036-T4, 2037-T4, 2038-T4, 5182-O, 6009-T4, 6010-T4, 6015-T4, AA6016, 6111, 5754, etc.

In addition, there are alloys with certain characteristics developed by some companies, such as AlMg5 and 483 alloys in France, GC45, GZ45, GC150, GV10, X660 of Kobe Steel in Japan, and AMg3 in Germany.

ABS must have good formability, strong surface smoothness, good weldability and excellent bake hardenability. The technical complexity of producing ABS and the investment in building ABS projects are the largest projects in the aluminum processing industry, which are larger than the production of aerospace aluminum alloy plates and strips.

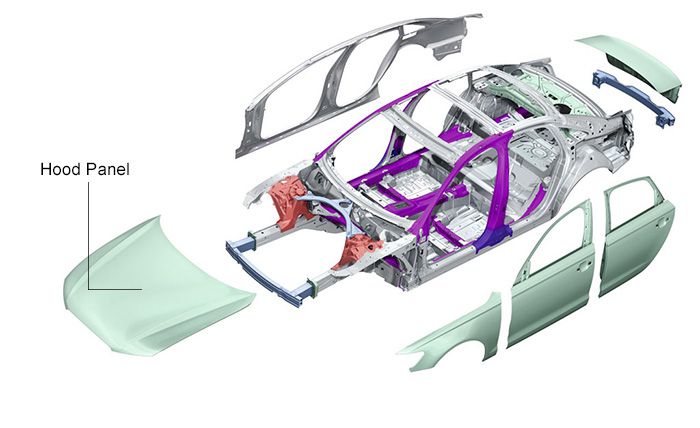

Aluminum alloys need to achieve four key technologies in order to realize the lightweight of automobiles: firstly, component structure design; secondly, material design; thirdly, forming technology; and finally, connection technology.

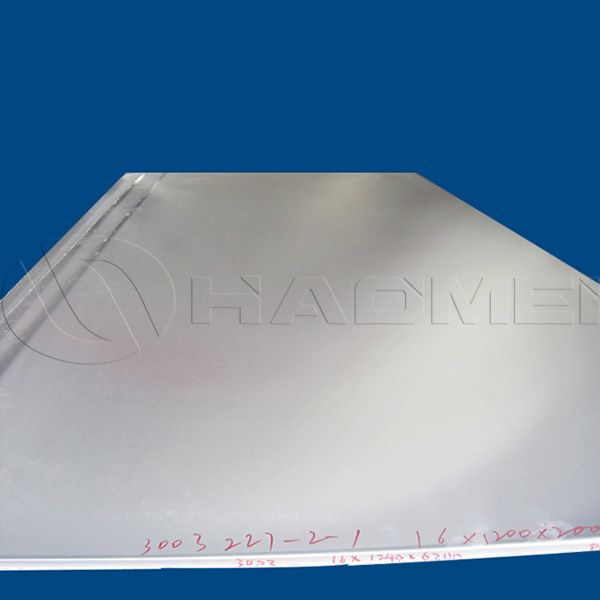

The yield strength of AA6016 before baking is 119MPa, and can reach 218MPa after baking. The performance of the 6016 aluminum sheet is basically consistent with the materials of these famous brands in the world. Another important property of this material is stability. We did an experiment and left the 6016 aluminum for 180 days, and its strength is basically very stable. Besides, it also has a good surface treatment.

In addition, the aluminum sheet’s molding performance is also very important for automobile lightweight. Usually, we use the forming limit diagram (FLC) as the most basic judgment basis for molding. Compared with steel, aluminum alloy is lighter in weight, but hot forming is not as good as steel, so there are still many problems in stamping and forming of aluminum alloy. One is cracking, and the other is relatively large rebound rate, which is due to its elasticity. Haomei Aluminum adopts simulation to simulate a series of problems such as cracking and wrinkling during molding, and finally achieve the effect we need.

6016 aluminum is one of the main 6xxx alloy grades and a very important alloy used in the automotive field. 6016 t6 is its main temper. At present, 6016 aluminum sheets have been able to meet the highest requirements of some automobile manufacturers for the outer panels.

At present, the aluminum alloys for car body in foreign countries mainly use 6000 series alloys, such as 6009, 6010, 6111, 6181A, etc. American automakers mostly use 6111 with higher strength, and in Europe, more 6016 with better formability is used. Haomei Aluminum generally supplies 5xxx and 6xxx aluminum alloys for automobile making.

Original Source:https://www.autoaluminumsheet.com/a/aa6016-for-abs-outer-panel.html

Tags: 6016 aluminum sheet ,

Prev:Al Alloy 7075 for ABS Body Parts

Next:5052 and 5083 Aluminum Sheet for Front Wing of Cars