What Are Uses of 5754 Aluminum in Car Making

In the wave of the automotive industry's transformation towards lightweight and environmental protection, 5754 aluminum sheet has become one of the core materials that promotes industry change with its excellent comprehensive performance. This Al-Mg alloy is characterized by medium strength, excellent corrosion resistance and excellent processability. It is widely used in all aspects of automobile manufacturing, from body structure to key components, showing irreplaceable advantages.

Core applications

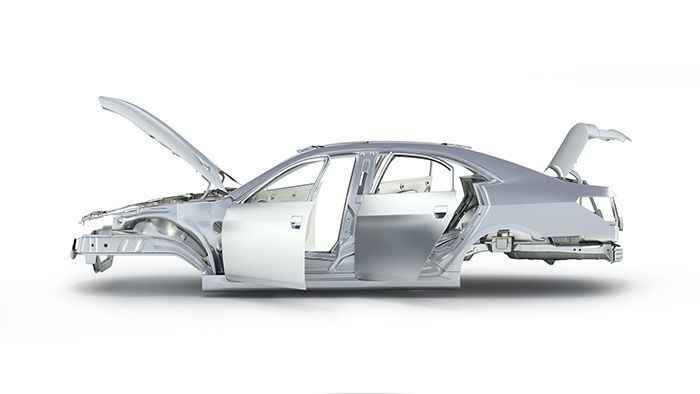

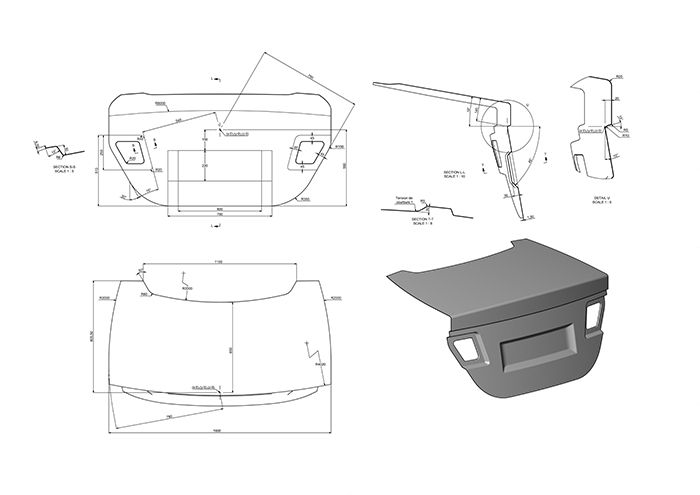

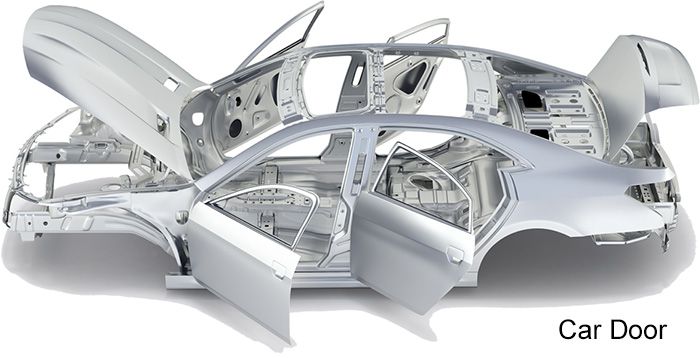

Body and structural parts

The high strength and lightweight properties of Al 5754 make it an ideal choice for body frames. It is also used to make doors, roofs and other covering parts. For example, the inner door panel of Tesla Model S uses 5754-O sheet, which is cold-formed to achieve complex curved surface design, taking into account both beauty and safety.

Chassis and suspension system

Chassis components have extremely high requirements for the impact resistance and corrosion resistance of materials. Chassis accessories made of 5754 aluminum alloy (such as suspension arms and subframes) can effectively absorb vibration energy during driving, while resisting the erosion of road salt water and gravel.

Core components of new energy vehicles

In the field of electric vehicles, 5754 aluminum alloy is more widely used:

Battery pack structure: The upper cover and bottom plate of the battery pack are made of 5754-O aluminum plate, with a thickness of usually 1.5-3mm, which can not only bear the weight of the battery pack, but also improve the insulation and heat dissipation efficiency through anodizing treatment.

Motor housing: After precision processing, 5754-h22 aluminum alloy can meet the requirements of the motor housing for sealing and fatigue resistance, and reduce weight by more than 40% compared with traditional cast iron materials.

Interior and functional parts

The easy processing of 5754 aluminum alloy makes it shine in the field of automotive interior. For example, the dashboard bracket and seat frame use 5754-h111 aluminum sheet.

Common tempers

5754 aluminum alloy is formed into various tempers through different processing techniques to meet differentiated needs:

O temper: Its tensile strength is 165-265MPa, and its elongation is ≥20%. It can be softened uniformly by short-time high-temperature annealing (500-530℃) in an air cushion furnace.

H111: It is used for body panels, with moderate strength (tensile strength 220-270MPa), and both formability and surface quality.

H32/H34: Through cold working and stabilization treatment, the tensile strength is increased to 240-280MPa, while maintaining good stress corrosion resistance.

H24: Its tensile strength is ≥230MPa. After long-term differential temperature annealing in a box furnace, the intergranular corrosion rate is ≤10mg/cm², which can meet the long-term service requirements in a high temperature environment of 130℃.

At present, 5754 aluminum alloy has gradually penetrated into the mainstream market from the exclusive material of early luxury models. With the continuous advancement of the automobile lightweight policy, the market demand for 5754 aluminum alloy is expected to grow at an average annual rate of 8%. Haomei Aluminum is one of the 5754 aluminum suppliers in China. Welcome to contact us directly if you need.

Original Source:https://www.autoaluminumsheet.com/a/what-are-uses-of-5754-aluminum-in-car-making.html

Tags: 5754 aluminum sheet ,

Prev:Automotive Aluminum Grade 7075 6101

Next:AW5754 3003 for Car Manufacturing