How About Stamping Performance of 5052 and 5754 in Automobiles

In the process of the automobile manufacturing industry's continuous pursuit of lightweight and high performance, aluminum alloys have gradually become an ideal choice for automobile parts manufacturing with their excellent comprehensive performance. As typical representatives of Al-Mg alloys, 5754 and 5052 aluminum sheets have shown unique advantages in the field of automobile stamping.

Alloy composition and properties

5052 aluminum alloy uses magnesium as the main alloying element, with a magnesium content between 2.2% and 2.8%, and also contains a small amount of manganese, chromium and other elements. This alloy ratio gives 5052 good corrosion resistance and can remain stable in a variety of environments, just like putting a layer of protective armor on automotive parts. A dense oxide film can quickly form on its surface, effectively blocking erosion by seawater, acid rain, etc., and is particularly suitable for automotive parts used in harsh environments.

5754 aluminum alloy also belongs to the Al-Mg alloy family, has medium strength, and exhibits a high strength level in non-heat-treated alloy aluminum plates. Its corrosion resistance is also excellent, and its good weldability and easy processing and forming characteristics make it very popular in automobile manufacturing. 5754 aluminium properties are listed in the following part.

Comparison of Mechanical Properties

Strength Performance

5052 aluminum alloy has medium strength, and its tensile strength is generally between 170 and 305MPa. Its strength is sufficient to meet the use requirements of many automotive parts, such as some structural parts of automobiles, while ensuring a certain strength, it can also achieve lightweight. The tensile strength of 5754 aluminum alloy is 190-240MPa, which also has medium strength and can provide reliable support for automotive parts. In some stamping parts that have certain strength requirements, such as some parts of the automobile chassis, 5754 aluminum alloy can do the job.

Plasticity and Elongation

The elongation of 5052 aluminum alloy is relatively high, generally between 12%-20%, which enables it to better withstand deformation without cracking during cold processing and has good cold stamping performance. In the annealed (O) state, its cold stamping performance is even better, and it can easily complete cold rolling, stamping, bending and other processes.

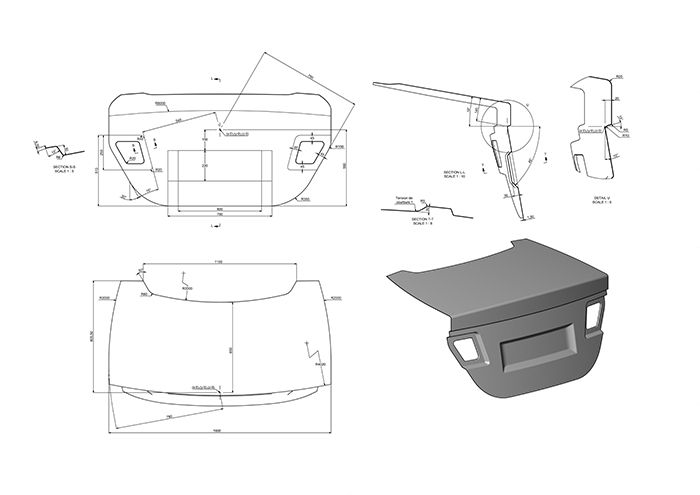

For some complex-shaped automotive covers, electronic product shells, etc., they can be formed in one go. 5754 aluminum alloy also has good plasticity, which can meet the requirements of automotive stamping parts for material plasticity and can be processed into various shapes during the stamping process.

Stamping processing performance

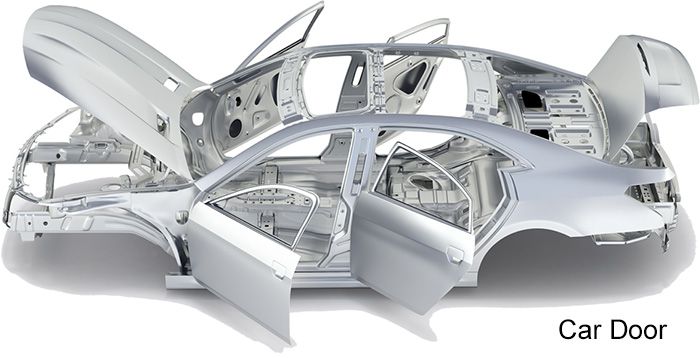

In terms of cold stamping, 5052 aluminum stamping performs outstandingly. As mentioned above, it can easily cope with the stamping requirements of complex shapes in the annealed state. In the automobile manufacturing workshop, 5052 aluminum coils are stamped into car doors, engine hoods and other parts with an accuracy of ±0.1mm and a yield rate of up to 98%.

When cold stamping, 5754 aluminum alloy can also adapt to the requirements of complex shapes for automobile stamping parts with good processing formability, but it may be slightly inferior to 5052 aluminum alloy in stamping of some extremely complex shapes.

Hot stamping performance

From the perspective of hot process plasticity, 5052 aluminum alloy can be hot deformed with a deformation rate of >80% when the forging and die forging temperature is 420-475°C, and the hot process plasticity is good. Although there is no clear data showing the hot stamping temperature range and deformation rate of 5754 aluminum alloy, it can be inferred from its good processing formability and wide application in automobile manufacturing that it can also perform well in hot stamping, but it may differ from 5052 aluminum alloy in specific process parameters.

Welding performance

In automobile manufacturing, welding is an important process for connecting stamping parts. 5052 aluminum alloy has good gas welding, arc welding, resistance welding, spot welding, and seam welding performance, but it tends to have crystallization cracks during argon arc welding. The weld has high strength and plasticity, and the weld strength reaches 90% - 95% of the base metal strength, but the weld airtightness is not high. It is recommended to use 5A03 alloy as solder to improve its airtightness and eliminate the tendency of cracks.

5754 aluminum alloy has good weldability and can maintain good strength and corrosion resistance after welding. It has obvious advantages in the manufacture of automotive parts that need to be welded, such as the welding of automotive chassis parts. 5754 aluminum alloy can make the connection more firm and reliable.

Original Source:https://www.autoaluminumsheet.com/a/how-about-stamping-performance-of-5052-and-5754-in-automobiles.html

Tags: 5052 aluminum sheet ,

Prev:5754 6061 Aluminum Plate for Aluminium Car Parts

Next:What Are ABS Aluminum Alloys