5754 6061 Aluminum Plate for Aluminium Car Parts

In the automotive industry, aluminum alloys have become key materials for achieving lightweight, performance and fuel efficiency improvements due to their excellent strength-to-weight ratio, good corrosion resistance and easy processing.

Among them, 5754 and 6061 aluminum sheets are widely used. Their unique performance characteristics determine their dominant position in the manufacturing of different automotive parts.

5754 aluminum sheet

5754 aluminium plate belongs to the 5000 series, and its main alloying element is magnesium, which gives it many properties suitable for automobile manufacturing. It has excellent corrosion resistance and performs well in marine and chlorine-containing environments, so it is often used in automobile parts that are susceptible to corrosion.

For example, the wheel cover of a car is exposed to the outside for a long time and is easily corroded by rain, mud and road salt. 5754 aluminum alloy can effectively resist these corrosion factors and extend the service life of the wheel cover.

The alloy has good welding performance. Al 5754 H111 can be welded by MIG, laser welding and other processes, and the joint performance after welding is stable, which makes it flexible for splicing and assembly in car body manufacturing.

In terms of comprehensive mechanical properties, its yield strength is in the range of 145-220MPa, and its elongation is greater than 12%, which can meet the strength requirements of car body panels and some structural parts.

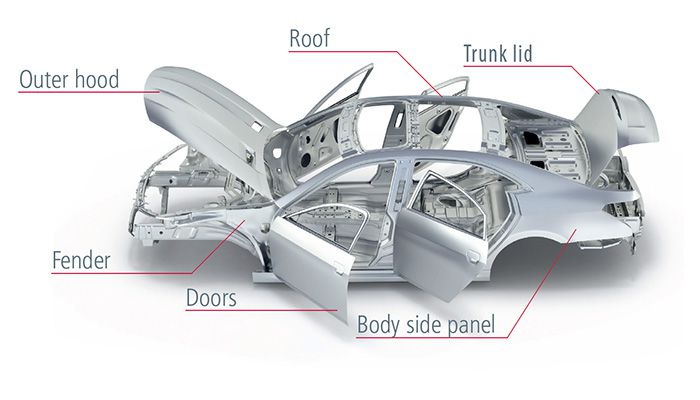

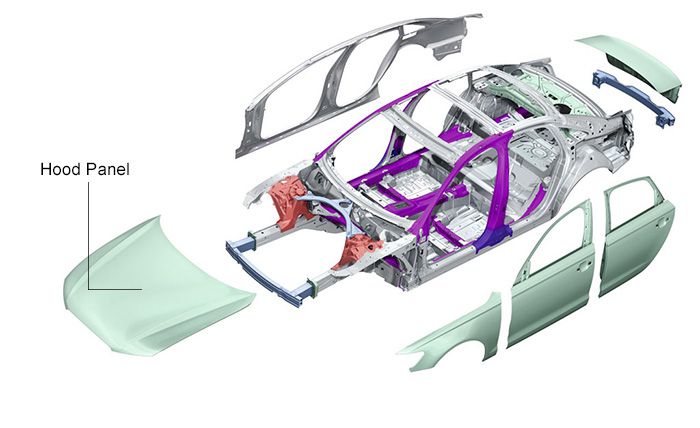

In the manufacture of body panels, 5754 aluminum alloy is often used for door inner panels, engine hood inner panels, etc. For example, in a certain electric vehicle, its battery tray frame uses 5754-H321 aluminum alloy, which reduces weight by 25% while meeting IP67 waterproof level and impact resistance requirements. In the field of tank truck manufacturing, 5754 aluminum alloy is also used to manufacture tanks and other parts due to its good formability and corrosion resistance.

6061 aluminum alloy

6061 aluminum alloy belongs to the 6000 series. Its main alloying elements are magnesium and silicon. It is a heat-treatable strengthening alloy. It has high strength and can reach a good strength level after heat treatment. It also has good corrosion resistance, weldability and processing performance.

In terms of automotive structural parts, 6061 aluminum plates are widely used. 6061 aluminum plates are often used in automotive subframes, which helps to reduce the weight of the vehicle body, improve fuel efficiency, and meet strength and durability requirements. 6061 aluminum alloy is used in doors, hoods, trunk lids and other parts of the vehicle body structure to achieve lightweight design. Wheels and suspension systems use its high strength and corrosion resistance to manufacture lightweight wheels and suspension components.

For example, the car seat frame often uses 3.0mm - 6.0mm 6061 aluminum plates, which take into account both strength and weight; the car wheels use 10mm - 20mm aluminum plates according to the wheel hub size; the car chassis often uses 8.0mm - 12.0mm aluminum plates to ensure the load-bearing capacity. In the field of new energy vehicles, its battery aluminum tray uses 3.0mm - 5.0mm aluminum plates, which can take into account both strength and lightness.

Performance comparison and selection basis

In terms of strength, the strength of 6061 aluminum alloy after heat treatment is higher than that of 5754 aluminum alloy. For automotive parts that bear large loads, such as suspension system parts and high-strength structural parts, 6061 is more suitable; while the strength of 5754 aluminum alloy can meet the requirements of body panels and some non-critical structural parts.

In terms of corrosion resistance, 5754 aluminum alloy performs better in resisting corrosion from seawater and chlorine-containing media due to the effect of magnesium. For example, for cars used in coastal areas, the wheel covers and lower parts of the car body that are easily exposed to corrosive media, 5754 aluminum alloy has more advantages; 6061 aluminum alloy also has good corrosion resistance and can meet the needs of automotive parts under normal conditions.

In terms of welding performance, both can be welded. 5754 aluminum alloy has good adaptability to welding process and stable performance of welded joints. When welding 6061 aluminum alloy, due to the silicon element, the welding process and parameter control requirements are slightly higher, but with good comprehensive performance, it is also widely used in automotive parts that need to be welded.

In terms of processing performance, 6061 aluminum alloy can be made into complex shapes through a variety of processing methods after heat treatment; the good plasticity of 5754 aluminum alloy enables it to perform well in forming processing, such as stamping forming of body panels. Welcome to inquire al 6061 price from us directly.

Original Source:https://www.autoaluminumsheet.com/a/5754-6061-aluminum-plate-for-aluminium-car-parts.html

Tags: 5754 aluminum sheet ,

Prev:AW5754 3003 for Car Manufacturing

Next:How About Stamping Performance of 5052 and 5754 in Automobiles