Different Tempers of 5052 Automotive Aluminum Sheet

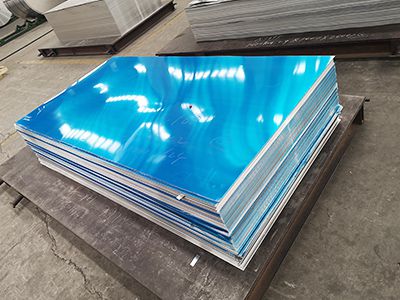

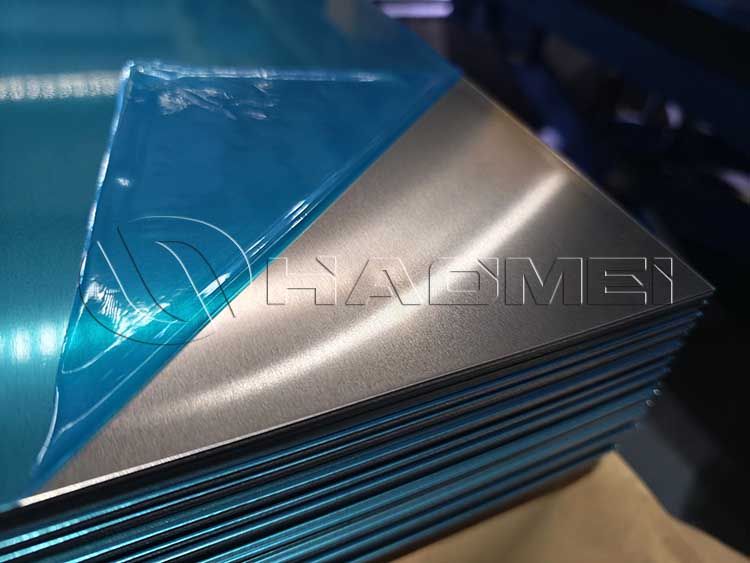

As an important member of the aluminum alloy family, 5052 aluminum sheet is widely used in the automotive industry for its excellent overall performance. Different 5052 aluminum tempers exhibits distinct properties, making it suitable for the manufacturing requirements of various automotive components.

5052-O aluminum

The O state is a fully annealed state. 5052 aluminum sheet in this state has lower hardness and strength, but exhibits excellent plasticity and ductility, making it easy to process into complex shapes.

In automotive interiors, 5052-O aluminum sheet is commonly used for instrument panel frames and seat frames. Instrument panels have complex shapes, and this state allows for precise shaping through stamping, bending, and other processes, providing support for internal instrument components.

Seat frames require ergonomic design, and its excellent formability meets these styling requirements while maintaining a certain level of structural stability. Furthermore, its high surface quality facilitates subsequent treatments such as anodizing and painting, enhancing the aesthetics of the interior.

5052-H32 aluminum

H32 aluminum sheet is produced through incomplete annealing and appropriate work hardening. It offers high strength and hardness while maintaining a certain degree of ductility and corrosion resistance.

This aluminum sheet is often used in automobile fuel tank manufacturing. It effectively resists fuel corrosion, ensuring long-term tank safety, and its processing performance meets the complex shapes and high-precision dimensional requirements of fuel tanks.

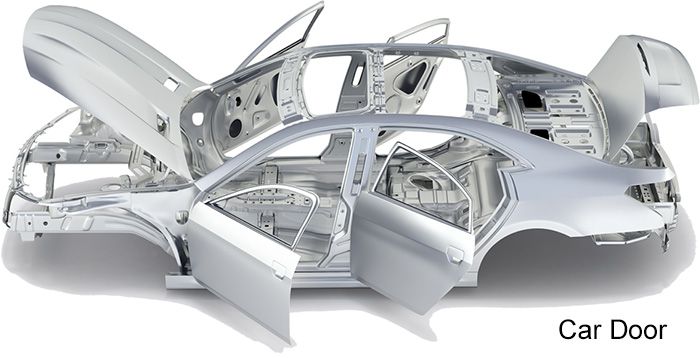

In body sheet metal parts such as doors and hoods, H32 aluminum sheet can withstand the stresses of daily use while being easy to process to ensure component precision and appearance.

It is also commonly used in bus trunk panels and anti-slip decorative panels. Trunk panels can withstand the weight of luggage without deformation, while anti-slip decorative panels can be processed to create a non-slip texture. Welcome to inquire 5052 h32 aluminum sheet specifications from Haomei Aluminum directly.

5052-H34 aluminum

H34 temper offers an excellent balance between strength and ductility, high tensile strength, and excellent corrosion resistance.

5052 h34 aluminum sheet plays a vital role in key structural components, such as some chassis support structures and certain suspension components. It withstands the complex stresses of road conditions during driving, ensuring the stability and reliability of the chassis and suspension systems, and ensuring driving safety. Its corrosion resistance also allows it to withstand harsh environments such as those containing moisture and salt, extending component life and reducing maintenance costs.

5052-H22 aluminum

H22 aluminum sheet is work-hardened and then partially annealed, offering excellent formability and moderate strength.

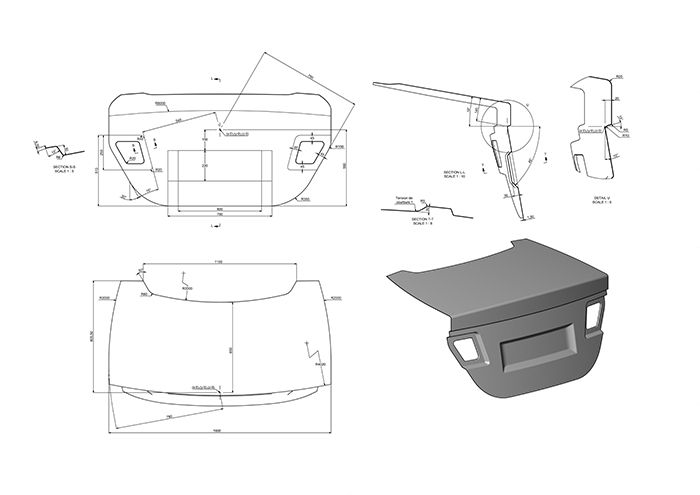

The engine hood requires a certain degree of strength to protect the engine while also adapting to the complex shapes of the engine compartment. H22 aluminum sheet meets these requirements.

Car doors, which are subject to frequent opening and closing, must withstand the forces of heavy use. This aluminum sheet ensures structural stability and is easy to process to achieve diverse exterior designs.

This aluminum sheet is also commonly used in trunk panels, accommodating the weight of luggage while also being easy to manufacture and install. Furthermore, it is widely used in the manufacture of non-structural components for transportation equipment such as railway carriages, buses, and trucks due to its comprehensive performance advantages.

5052-H114 aluminum sheet

H114 aluminum sheet undergoes work-hardening and stabilization treatments, resulting in excellent flatness and corrosion resistance.

For automotive interior trim panels such as center console trim and door trim, H114 aluminum sheet ensures a smooth surface, enhancing the interior's aesthetics and quality. The instrument panel uses 5052 h114 aluminum plate to ensure flatness to clearly display instrument information. At the same time, its corrosion resistance can resist minor corrosion caused by hand sweat, detergents, etc., extending the service life of the instrument panel and maintaining a good appearance.

Original Source:https://www.autoaluminumsheet.com/a/different-tempers-of-5052-automotive-aluminum-sheet.html

Tags: 5052 aluminum sheet ,

Prev:Aluminium in Car Interior

Next:What Are 3003 Aluminum Applications