5083 5754 Aluminum for Automobile Lightweight

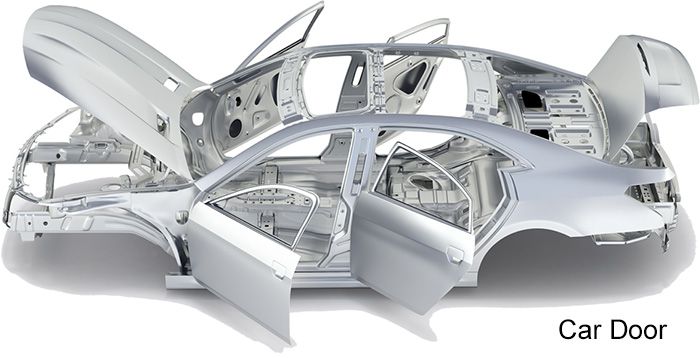

Automobile lightweighting can be achieved through the comprehensive application of three aspects, namely material lightweighting, structural lightweighting and process lightweighting. With the continuous improvement and maturity of design methods and manufacturing processes, automobile lightweighting is focusing on improving the use of lightweight materials.

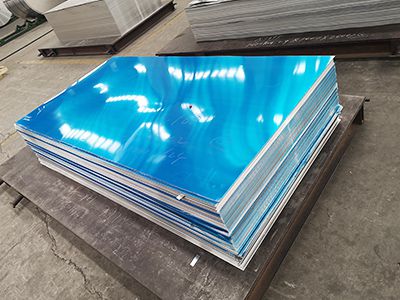

5083 aluminum plate, also called 3.3547 aluminum, is a widely used anti-rust aluminum. This alloy has high strength, high plasticity and weldability, and is not easily deformed during processing. With its excellent properties, 5083 aluminum alloy is widely used in automobile manufacturing fields, such as interior panel, air reservoirs, automobile bottom guards, new energy vehicle battery side panels, etc.

Only part of the aluminum alloy overall body requires spot welding. There are fewer welding points, the processing process is shortened, and no anti-rust treatment is required. Therefore, the assembly efficiency of the car can be significantly improved.

In addition, aluminum alloys have low and mild corrosion rates during use, making them easy to recycle. Since the energy used to produce parts using recycled aluminum is much lower than that of primary aluminum, the application of recycled aluminum materials in future automobiles will be increased.

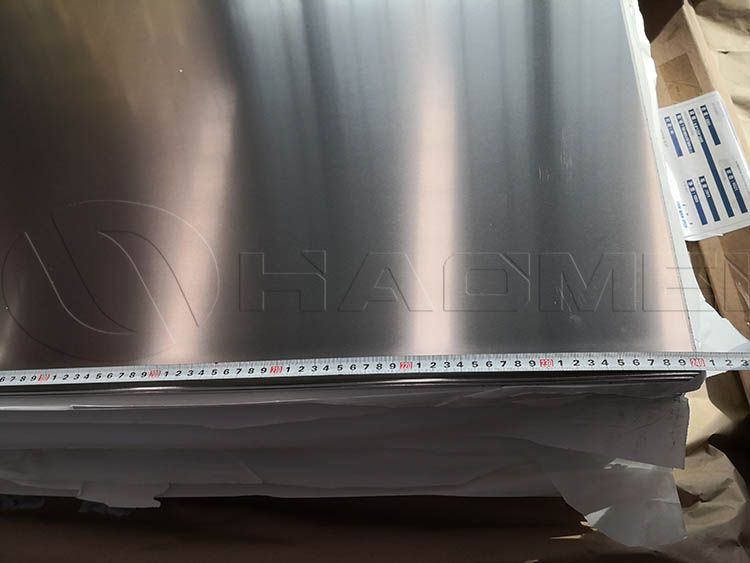

5754 aluminum sheet, also called 3.3535 aluminium are often stamped to form door linings, with high forming rate and good quality. In order to reduce production costs and improve efficiency, the aluminum processing industry is also exploring the feasibility of producing aluminum alloy automotive sheets by continuous casting and rolling(CC).

Federal Aluminum Research has confirmed that the 5754 aluminum alloy produced by the CC method can meet the requirements of automobile companies in terms of mechanical properties, corrosion resistance, welding performance, and formability.

Challenges in the application of aluminum alloys in automobile lightweight

1. Insufficient accumulation of material parameters

At present, some automobile manufacturing companies have carried out research on the knowledge and applications of aluminum alloy materials, but the research is not comprehensive enough and the application scope is small. In addition, the production technology and processing technology of aluminum alloys for automobile are immature and the production experience is relatively little.

2. Connection technology

Most of the workpieces of passenger car bodies are connected by welding, and the welding technology of aluminum is much more difficult than that of steel. Therefore, how to improve the welding performance of automobile aluminum alloy covering parts and improve the welding quality has become an important issue to expand the use of aluminum alloy in automobile coverage.

3. Painting performance

The pre-painting process of aluminum alloy is basically the same as that of steel. However, during the traditional phosphating treatment of steel plates, the content of free fluoride ions in the phosphating solution is low and cannot corrode the aluminum plates, resulting in poor quality of the phosphating film generated on the aluminum plates. The diversification and complexity of the pre-painting process for aluminum alloy will become a major challenge for the application of aluminum alloys in automobiles.

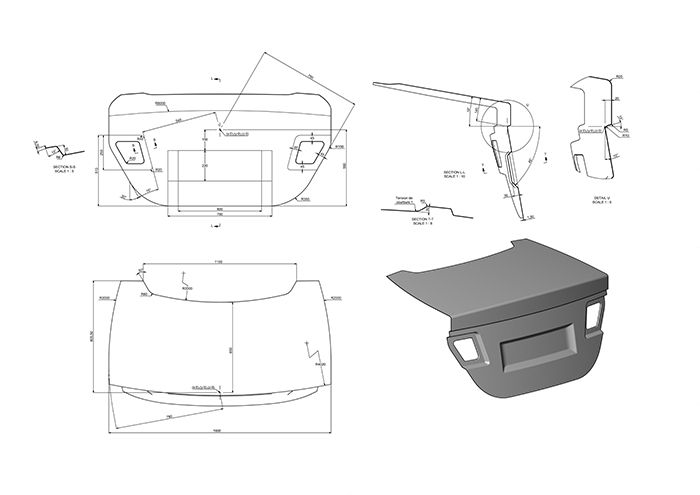

4. Stamping technology

The main forming method of automobile body components is stamping. Compared with steel, which has been widely studied and used, the stamping technology of aluminum alloy sheets is not yet mature and there are a lot of problems. Therefore, in the future, the main factors affecting the stamping performance of aluminum alloy sheets should be comprehensively considered, such as process parameters, fillet size, material properties,etc.

Original Source:https://www.autoaluminumsheet.com/a/5083-5754-aluminum-for-automobile-lightweight.html

Tags: 5083 aluminum plate ,

Prev:What Does Aluminum Do to The Car Body

Next:6xxx Aluminum Alloys for Electric Vehicles and Race Car