5052 Aluminum Sheet for Cars

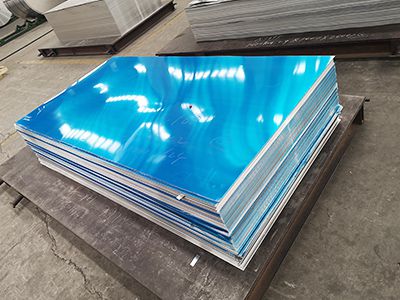

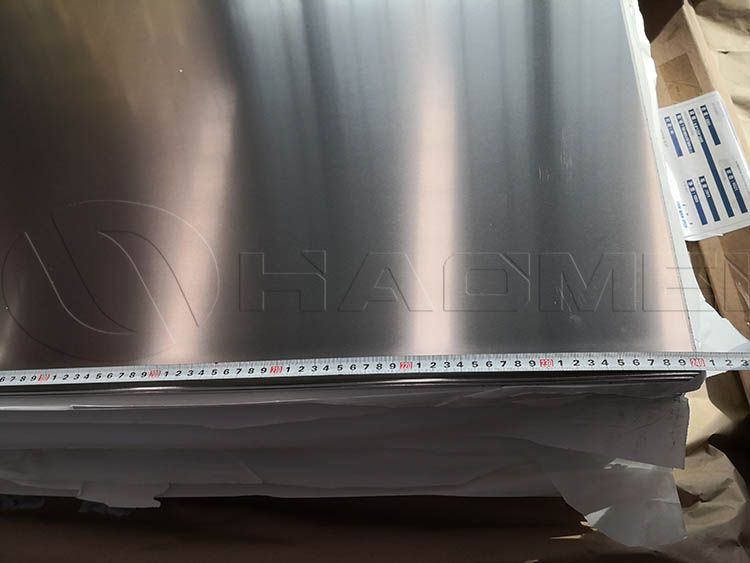

The core advantage of 5052 aluminum sheet for cars is its "balanced performance." Its main alloying element is magnesium (2.2%-2.8%), supplemented with small amounts of manganese and chromium to optimize performance. It is a non-heat-treated strengthening alloy, with performance controlled solely through cold working or annealing.

The application of 5052 aluminum sheet covers passenger vehicles (both pure electric and hybrid) and some commercial vehicles, including gasoline-powered cars and new energy vehicles (pure electric and hybrid). Different components require different performance conditions, resulting in variations in the material's state (O temper, H32 temper, H112 temper, etc.).

Gasoline-Powered Cars

The core requirement for gasoline-powered vehicles is to reduce vehicle weight to improve fuel economy while ensuring the long-term reliability of components. 5052 aluminum sheet has mature applications in fuel tanks, body panels, and interior parts, suitable for passenger cars, SUVs, and light trucks.

1. Automotive Fuel Tanks/Fuel Lines

Fuel tanks and fuel lines are the "lifeline" of gasoline-powered vehicles, requiring constant contact with fuel, resistance to vibration, and protection against environmental corrosion. The corrosion resistance and weldability of 5052 aluminum sheet play a crucial role in this application.

The material is primarily available in O and H32 tempers: The O temper (annealed, commonly known as the soft temper) boasts an elongation exceeding 25%, excellent formability, and is suitable for deep-drawing fuel tank shells, enabling complex tank structure designs.

The H32 temper (semi-work hardened) has a tensile strength of up to 220 MPa and an elongation exceeding 10%, offering a balance of strength and toughness, making it suitable for components requiring a certain load-bearing capacity, such as fuel lines and fuel tank flanges.

Currently, most mainstream passenger cars use 5052 aluminum sheet instead of traditional steel for their fuel tanks, reducing weight by 30%-40% and extending service life by 2-3 times.

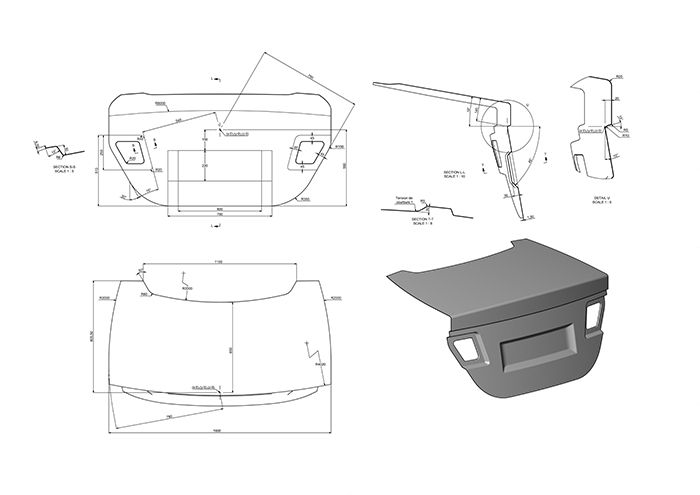

2. Body Panels/Protective Components

5052 aluminum sheet is commonly used for low-load components in body panels, such as engine panels, brake dampers, heat shields, and in some models, door panels and trunk lid panels. The material is primarily in the H32 temper, which offers moderate strength, is less prone to cracking after stamping, and has excellent weldability, meeting the assembly requirements of body components.

3. Interior Trim Components

Polished and anodized 5052 aluminum sheet has an excellent surface texture and can be used to manufacture components such as dashboard brackets, interior trim strips, and seat frames, balancing aesthetics and lightweighting. The material is mostly in the O temper, due to its good plasticity, allowing it to be processed into complex decorative structures such as curved and irregular shapes. Furthermore, surface treatments can produce a variety of colors, enhancing the interior's perceived quality.

New Energy Vehicles

New energy vehicles (especially pure electric vehicles) have an even more urgent need for lightweighting, and the lightweight and corrosion-resistant properties of 5052 aluminum sheet perfectly match the application requirements of its motor and battery peripheral components.

1. Motor Cover Plate

The motor cover plate is a critical protective component of the electric drive system in new energy vehicles. It must withstand the vibration and impact of the motor during operation, while also possessing good heat dissipation and corrosion resistance. 5052 aluminum sheet is one of the mainstream material choices for this component.

The material states primarily used are H32 and H112: H32 is suitable for thin-plate motor cover plates (thickness 0.7-2.5mm), balancing strength and formability, and can be processed into complex shapes through stamping to meet the spatial layout requirements of the motor compartment. H112 is a work-hardened state, suitable for thick-plate motor cover plates (thickness 3-6mm), offering stronger load-bearing capacity and meeting the protection requirements of high-power motors.

For example, the drive motor cover plate of the Tesla Model 3 uses 5052-H32 aluminum sheet, 1.5mm thick, achieving both lightweight design and effective protection of the motor from external dust and moisture corrosion, ensuring stable operation of the electric drive system.

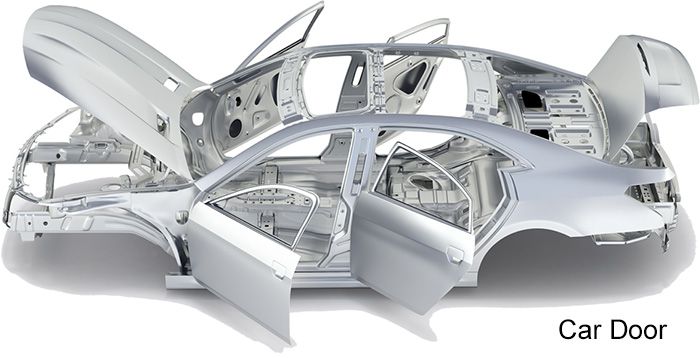

2. Body Side Panels/Inner Panels

The lightweight of new energy vehicle bodies directly impacts range. The application of 5052 aluminum sheet in components such as body side panels and door inner panels is a crucial weight-reduction method. The material is primarily in the H32 state, which facilitates cold stamping and forming, allowing for the creation of complex curved surface structures for body side panels. It also boasts excellent weldability, ensuring the structural strength of the body.

3. Battery Peripheral Protective Components

Components such as heat shields and protective baffles around the battery pack in new energy vehicles require temperature resistance, corrosion resistance, and lightweight properties. 5052 aluminum sheet meets these requirements.

It is primarily in the H32 state, possessing the strength to withstand the installation load of the battery pack. Its good formability allows it to adapt to irregular battery pack structures, while its corrosion resistance prevents aging of components around the battery due to humid environments. Welcome to buy 5052 H32 aluminum sheet from Haomei Aluminum directly.

Commercial Vehicles

In addition to passenger vehicles, 5052 aluminum sheet is also used in commercial vehicles such as light trucks and medium-duty trucks, mainly focusing on components such as fuel tanks and cargo box protective panels.

For example, the fuel tank of Foton Aoling light truck uses 5052-H32 aluminum plate with a thickness of 2.0-2.5mm, which can withstand the vibration and impact during heavy-duty transportation and resist the corrosion of wind, rain and salt spray during long-distance transportation, thus extending the service life of components; the side protection plates of some commercial vehicles use 5052-H112 thick plates (3-5mm thick), which balances lightweight and structural strength and reduces transportation energy consumption.

Original Source:https://www.autoaluminumsheet.com/a/5052-aluminum-sheet-for-cars.html

Tags: 5052 aluminum sheet ,

Prev:Growth Points in The Application of Aluminum in Car Bodies