6xxx Aluminum Alloys for Electric Vehicles and Race Car

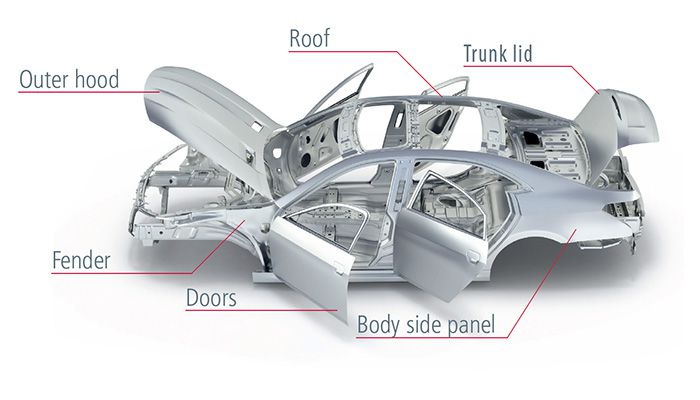

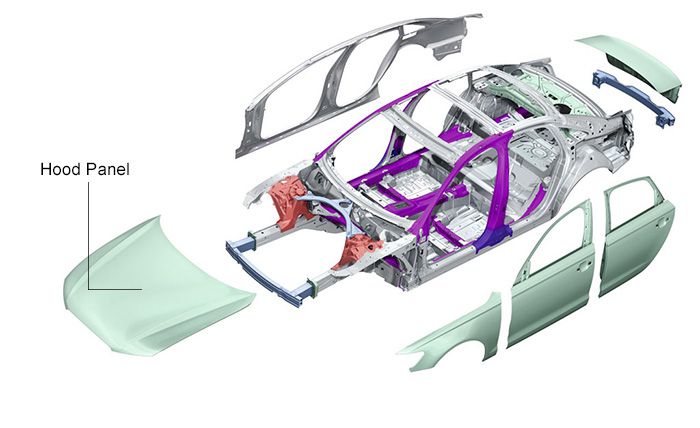

Due to the key role of lightweighting in energy saving and emission reduction of transportation vehicles, lightweight materials have been widely used in the automotive field in recent years. Compared with traditional steel, automotive aluminum sheets have low density, excellent corrosion resistance and are easy to recycle. Therefore, the application of aluminum alloys in making electric vehicles and race car s increasing year by year. At present, the aluminum alloy sheets used for stamping automobile bodies are mainly three grades of aluminum alloys: AA6016, AA6022 and AA6111.

Because of their good plasticity and the ability to achieve artificial aging during the paint baking process after forming to obtain higher strength, they are even used in cars produced by well-known car brands. For example, the body panels of the Audi A8 use this material.

6111 aluminum is an aluminum alloy used for automotive panels. Its advantageous properties include corrosion resistance and resistance to precipitation hardening. The recrystallization texture of 6111 aluminum alloy sheet is mainly composed of two texture components.

6111 aluminum is an aluminum alloy used for automotive panels. Its advantageous properties include corrosion resistance and resistance to precipitation hardening. The recrystallization texture of 6111 aluminum alloy sheet is mainly composed of two texture components.

After two years of natural aging, the strength of the 6016 aluminum alloy plate has increased slightly. When the 6016 aluminum alloy plate is used for automobile covering parts, the painting process after stamping is beneficial to improving the anti-dent performance of the covering part.

The requirements for aluminum alloy automotive sheets include good formability, certain aging stability, good bake hardening, high dent resistance, good flanging, good surface gloss, good surface treatment and coating performance.

These seven properties of aluminum alloy automobile sheets are both interrelated and contradictory. How to improve the alloy composition and adjust process parameters to obtain the best comprehensive performance and meet the requirements of stamping forming of car panels is the main goal of automobile sheet research and development. Therefore, the production process of aluminum automobile sheets is very complex, requiring long-term exploration and continuous improvement, and it is inseparable from close cooperation with downstream users.

The unique processes for the production of aluminum sheets mainly include solution quenching, pre-aging, and surface treatment processes.

1. Solid solution quenching and pre-aging treatment

6xxx aluminum alloy is bake hardenable, and the hardness will increase significantly when it is painted and baked in the automobile factory. Therefore, the supply status of 6xxx aluminum alloy plate is actually pre-aged T4P.

It is required that the uncoiled strip be heated to the solution treatment temperature in a short period of time and then enter the heat preservation area. After a short period of heat preservation, immediately enter the quenching area for strong wind quenching.

In order to improve the baking (BH) performance of aluminum alloys, the solution treatment temperature can be appropriately increased, but not too high to avoid over-burning. At the same time, by increasing the solution treatment temperature, the remaining second phase particles will be reduced, and the bending performance of the material will be better.

Pre-aging treatment is carried out after strip straightening and passivation. The pre-aging temperature is not high, generally between 70 and 110°C. Too high a temperature is detrimental to the strength after baking.

2. Surface treatment

The straightened aluminum sheet like en aw 6016 t4 needs surface treatment, which is an important process in the production of aluminum alloy automotive panels.

Original Source:https://www.autoaluminumsheet.com/a/6xxx-aluminum-alloys-for-electric-vehicles-and-race-car.html

Tags: 6111 aluminum ,

Prev:5083 5754 Aluminum for Automobile Lightweight

Next:3003 and 7075 Car Aluminum Stock