Are Aluminum and Aluminum Alloys The Best Material for Car Manufacturing

The density of aluminum is small (2.7 g/cm³), which is about 1/3 of steel (7.8 g/cm³). Replacing steel with aluminum alloy can reduce weight by about 50%. Since the surface of aluminum is easily anodized to form a dense and stable oxide film (passivation), it has good corrosion resistance. Aluminum has good castability. Because aluminum has a low melting temperature and good fluidity, it is easy to manufacture parts of various complex shapes.

Aluminum alloys are formed by adding one or several elements to aluminum. Aluminum alloys can improve strength and hardness compared to pure aluminum. In addition to solid solution strengthening, some aluminum alloys can also be strengthened by heat treatment, so that the tensile strength of some aluminum alloys can be more than 600 Mpa. The thermal conductivity and electrical conductivity are 3 times that of steel.

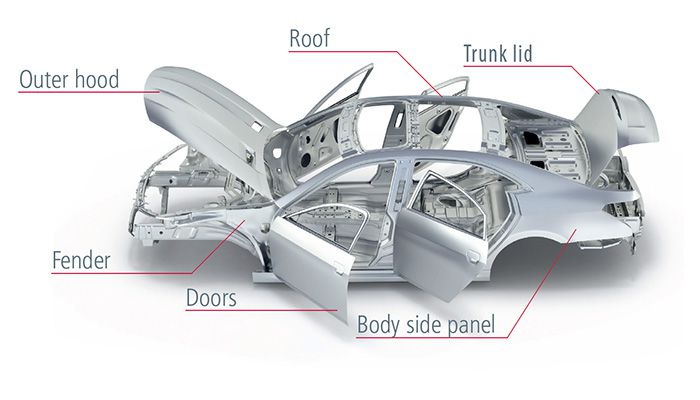

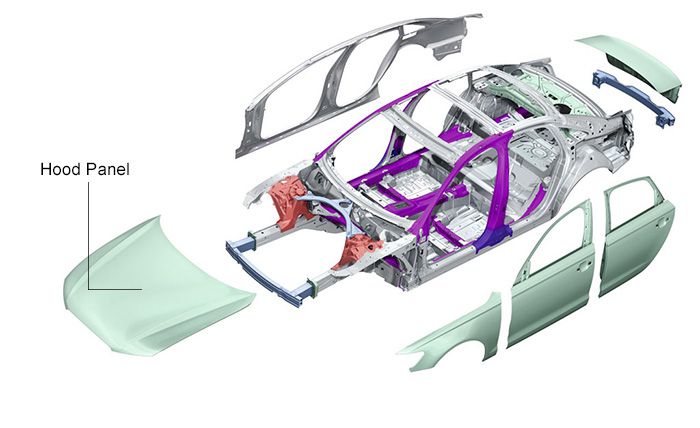

The aluminum alloys used for automobile body panels mainly include 2000 series, 5000 series and 6000 series alloys. From the perspective of materials required for automobile bodies and their processing characteristics, 2000 series and 5000 series are mainly used as inner panels of automobile panels, while 6000 series is mainly used for the outer panels of automobile panels. 5000 series and 6000 series automotive aluminum sheets are often used to replace traditional steel panels like aluminum alloy 5754.

The performance requirements for aluminum alloy sheets for car manufacturing are: in addition to mechanical properties and corrosion resistance that meet standards and specifications, they should also have the following properties:

1. Good formability, low yield-to-strength ratio and high forming limit.

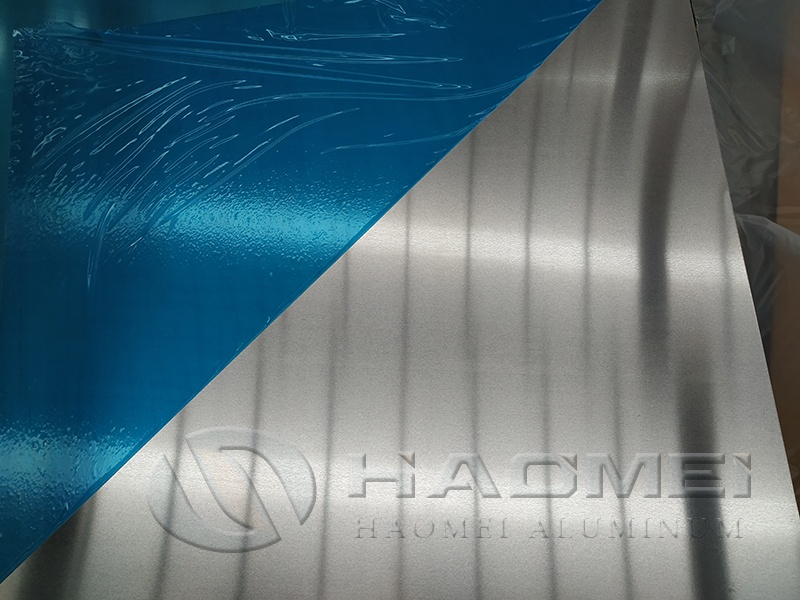

2. Smooth surface.

3. Good welding performance. In order to meet the process performance requirements of welding processing of automobile parts, aluminum alloy plates need to have good welding performance.

4. Good baking hardening performance.

5. High dent resistance.

6. Excellent surface treatment and coating performance.

7. Certain anti-aging stability performance.

Comparison of 6xxx series and 5xxxx series aluminum alloys for car making

As mentioned before, aluminum alloy automobile body panels mainly include 6xxx series and 5xxx series alloys. Typical grades include AA6014, 6016, 6111, 6022, 6181, 5052, 5182, 5754 and other aluminum alloys; the thickness specifications of aluminum plates for cars are generally 0.7-2.0mm.

6xxx Al-Mg-Si(-Cu) alloy

Al-Mg-Si-(Cu) alloys are widely used in automotive panels and other fields due to their high strength and good formability. The requirements for this type of alloy are to have good plasticity before baking and high precipitation hardening ability during the baking process, that is, to have a high paint hardening response.

Al-Mg-Si-(Cu) alloy is an aluminum alloy that can be strengthened by heat treatment and has good formability, strong corrosion resistance, high strength and good high temperature resistance.

5xxx aluminum alloys

It is an aluminum alloy that cannot be strengthened by heat treatment. It has the characteristics of medium strength, good corrosion resistance, good processing performance and good welding performance.

It is easy to produce delayed yielding and Leders lines and when the grain size is >100μm, the plate is prone to the "orange peel effect", so it is usually used to make inner panels of the car body.

Original Source:https://www.autoaluminumsheet.com/a/are-aluminum-and-aluminum-alloys-the-best-material-for-car-manufacturing.html

Tags: automotive aluminum sheet ,

Prev:Production Technology Analysis of Automotive Aluminum Sheet

Next:Why Is Aluminum Alloy Used for Automobile Hood