Aluminium 5754 H111 H114

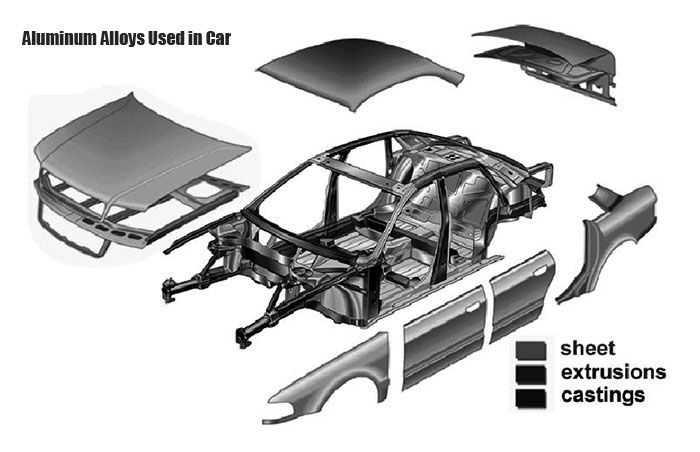

In the automotive manufacturing industry, aluminum alloys are favored for their excellent comprehensive properties, and 5754 aluminum alloy is a typical representative. It belongs to the Al-Mg alloy system, and is widely used in the fields of automotive parts manufacturing due to its medium strength, good corrosion resistance, weldability and easy processing and forming.

5754 aluminum alloy has different heat treatment states, among which H111 and H114 are more common in the automotive industry, and they have certain differences in performance and characteristics.

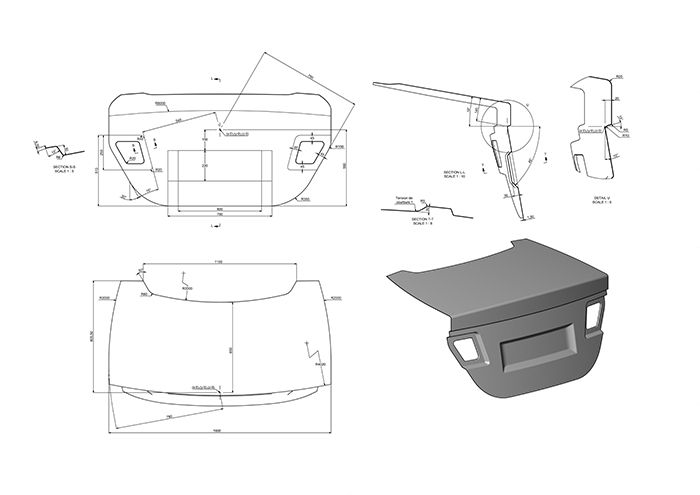

5754 aluminum sheet has the characteristics of low density and high strength, which can effectively achieve the lightweight of the vehicle without affecting the safety of the vehicle. At the same time, its good machinability and corrosion resistance make it an ideal material for automobile manufacturing.

In the manufacture of truck compartments, 5754 aluminum alloy is often used for the body skin and truck body. Compared with steel, it is lighter, which can reduce the overall weight of the vehicle and help reduce energy consumption.

In terms of welding, 5754 aluminum alloy has strong weldability, low tendency of welding cracks, and high strength of weld and base metal. Its tensile strength σb is between 165-265MPa, and it has good ductility.

5754 H111 Aluminum Alloy

Aluminium 5754 h111 has specific performance characteristics. From the perspective of mechanical properties, according to relevant standards (such as BS EN 485 - 2:2008), for aluminum plates with a thickness of 0.2mm to 6.00mm, the minimum non-proportional elongation strength is 60MPa, the tensile strength is between 160-200MPa, the minimum elongation of 50mm gauge length is 12%, and the Brinell hardness is 44HB.

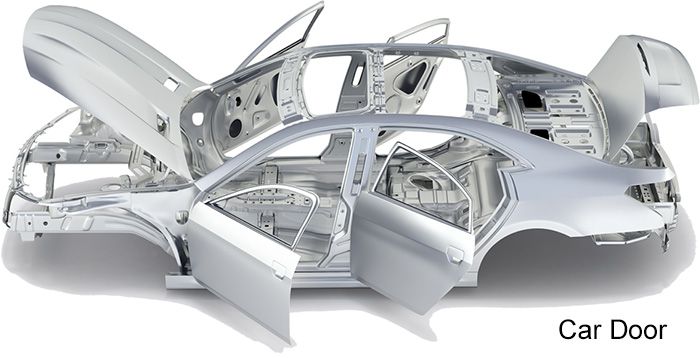

Aluminum alloy in this state has good formability and can meet the manufacturing needs of some automotive parts with high requirements for sheet forming, such as some complex-shaped parts of car doors. It has good corrosion resistance and is especially suitable for some automotive structural parts that have certain requirements for corrosion resistance but not particularly high strength requirements.

In the manufacture of automotive interior parts, such as some decorative panels, 5754 H111 aluminum alloy can play its advantages of good formability and good corrosion resistance, which can not only produce beautiful shapes, but also ensure long-term use without corrosion in the car environment.

5754 h114 aluminum alloy

The performance of 5754 H114 aluminum alloy is different from that of H111. According to BS EN 485-2:2008, for aluminum plates with a thickness of 0.2mm to 6.00mm, the minimum non-proportional elongation strength is increased to 80MPa, the tensile strength range is 190-260MPa, the minimum elongation of 50mm gauge length is also 12%, and the Brinell hardness reaches 52HB. It can be seen that the strength of aluminum alloy in H114 state is significantly improved compared with H111.

This makes it more advantageous in some automotive parts applications that require higher structural strength. For example, the 5754-H114 5 bar aluminum tread plate (conventional thickness 5mm) used in the spiral staircase inside the wind power tower takes advantage of its excellent anti-slip performance, high hardness and strength.

In the automotive field, if 5754 aluminum alloy is used for some supporting parts of the car chassis, the en aw 5754 h114 will better meet the strength requirements than H111 to ensure that it can withstand various complex stresses during vehicle driving. Its corrosion resistance is also excellent. For automotive parts used in some harsh environments, H114 aluminum alloy can ensure a longer service life.

Original Source:https://www.autoaluminumsheet.com/a/aluminium-5754-h111-h114.html

Tags: 5754 aluminum ,

Prev:Which Aluminium Alloys Are Used in Cars

Next:What Is Automotive Grade Sheet Metal