6111 and 6016 Aluminum Automotive Sheet

Since the 1970s, countries like the US, Europe, and Japan have been developing aluminum alloys for automobiles. In the early 1980s, North America and Europe successfully developed high-Cu-content 6111 aluminum alloy and low-Cu-content 6016 aluminum automotive sheet, respectively. These two alloys quickly became the core choices for automotive body panels globally.

The overseas market's preference for these two alloys is essentially due to the precise match between their performance and the needs of the automotive industry, which can be summarized into three core demands:

First, the rigid demand for lightweighting and energy conservation and emission reduction. Against the backdrop of increasingly stringent global carbon neutrality goals and fuel efficiency regulations, vehicle weight reduction has become a core focus for automakers.

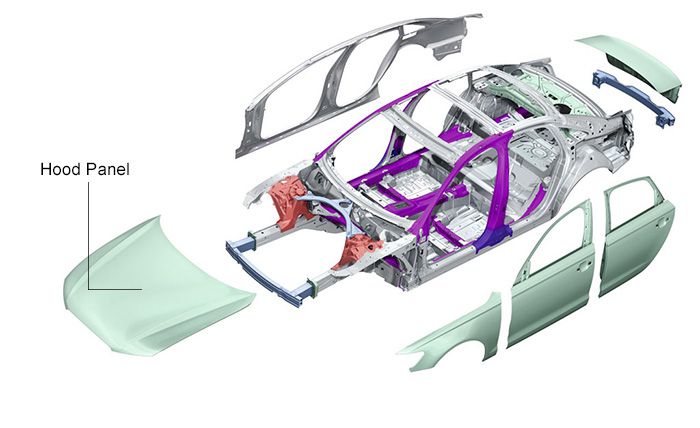

Data shows that when 6016 aluminum alloy is used for door panels, it can achieve a weight reduction of over 40%, while 6111 aluminum alloy, when used in components such as the hood, also brings significant weight reduction, directly contributing to an approximately 8% improvement in fuel efficiency.

This lightweight advantage is crucial for reducing fuel consumption in traditional gasoline vehicles and increasing the driving range of new energy vehicles, becoming the core driving force behind overseas automakers' choice of these two alloys.

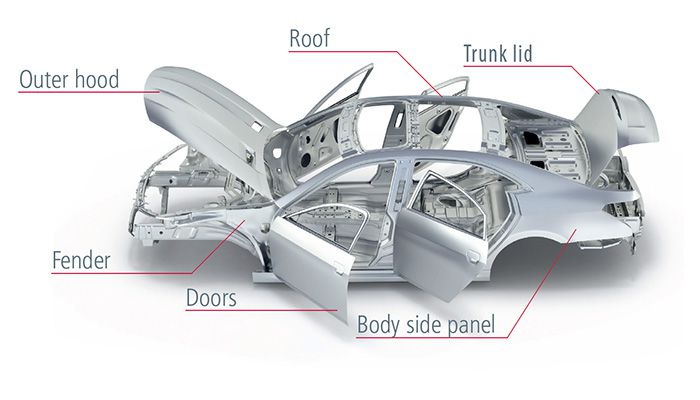

Secondly, there's the requirement for compatibility with automotive manufacturing processes. Automotive exterior panels (hoods, doors, trunk lids, etc.) require complex stamping, bending, and assembly processes, demanding extremely high formability and dimensional stability from the materials.

Both 6111 and 6016 aluminum alloys possess low springback rates and high formability limits, with a springback angle of only 3-5° after stamping. This effectively reduces dimensional deviations, ensures assembly accuracy, and minimizes mold wear. This excellent processing adaptability allows them to easily handle the stamping requirements of complex curved surfaces, perfectly aligning with the design concepts of high-end European and American vehicles.

Finally, there's the economic requirement for total lifecycle costs. These two alloys not only have a smooth surface and no orange peel texture after painting, resulting in excellent visual appeal, but also possess good corrosion resistance—the naturally formed oxide film effectively resists rust, reducing later vehicle maintenance costs.

More importantly, both belong to the 6xxx series alloys, which have high recyclability, aligning with the "circular economy" development trend in the overseas automotive industry and further enhancing their market competitiveness. Currently, the US market primarily uses 6111 auto body panel to manufacture 0.9-1.0mm thick outer panels, while Europe prefers 1-1.2mm thick 6016 aluminum alloy, creating an application pattern that precisely matches regional needs.

China's Production Technology Level

Compared to the decades of technological accumulation in Europe and America, China's research and development and production of 6111 and 6016 automotive aluminum alloys started later. However, in recent years, thanks to policy support and enterprise innovation, it has achieved a breakthrough from "nothing" to "something," gradually acquiring large-scale production capabilities.

Currently, China has made two major advancements in the production of 6111 and 6016 aluminum alloys: First, the formation of large-scale production capacity. We can stably produce 0.7-1.2mm thick plates, widely used in the body manufacturing of domestic automakers such as Geely and Haima. Second, breakthroughs in core processes.

Domestic companies have introduced advanced equipment such as German SMS rolling mills, establishing a "1+4" hot continuous rolling production line. Through optimizing heat treatment processes such as solution treatment and pre-aging, a balance between material strength and plasticity has been achieved.

For example, the T4P process, which involves solution treatment at 560℃ for 1 min followed by pre-aging at 80℃ for 6 h, allows 6016 aluminum alloy to maintain high plasticity before stamping, and the yield strength increase after painting is ≥80MPa, with performance approaching the international advanced level.

Original Source:https://www.autoaluminumsheet.com/a/6111-and-6016-aluminum-automotive-sheet.html

Tags:

Prev:Which Vehicles Use A Lot of Aluminum

Next:Growth Points in The Application of Aluminum in Car Bodies