5000 and 7000 series Alloys for Railcars

Railcars made of aluminum alloys are a huge family: high-speed railways, medium- and low-speed maglev lines, subways, elevated urban rails, urban express rails, intercontinental expressways, urban monorails, maglev vehicles, etc.

Maglev vehicles must be all-aluminum regardless of speed. The so-called all-aluminum means that under the current technical conditions, all parts that can be made of aluminum alloy are made of aluminum.

There are two types of monorail vehicles: suspended and straddling. The aluminum rate of urban rapid rail transit vehicles is 30%-40%. The development of all-aluminum vehicles still has considerable potential, and it is still a key area to promote aluminum applications.

Under today's technical conditions, high-speed rail vehicle bodies are made of aluminum, more than 85% of which are extruded profiles, and the remaining 15% are flat-rolled aluminum sheets, castings and forgings. In addition, some aluminum is also used in vehicle internal facilities such as luggage racks, sanitary facilities, storage cabinets, etc., and the construction of air conditioning and ventilation systems, lighting and communication systems, stations and other facilities also requires some aluminum materials.

The application of aluminum in rail transit improves the payload of rail trains, saves fuel, and reduces vehicle maintenance costs. Due to the reduced weight, rail trains have good adaptability to high-speed, multi-turn, undulating routes and harsh environments, and their operation is easier to control and more stable.

Under normal circumstances, high-speed trains with speeds exceeding 250 kilometers per hour use aluminum alloy materials in large quantities. The 7xxx aluminum alloys used in high-speed trains include 7N01-T4, 7020-T6, 7003,etc.

Alloy and temper | Rp0.2(MPa) | Rm(MPa) | A50mm(%) |

7N01-T4 | ≧200 | ≧320 | ≧12 |

7N01-T5 | ≧245 | ≧325 | ≧10 |

7020-T6 | ≧280 | ≧350 | ≧10 |

7003-T5 | 260 | 310 | 10 |

The C80 coal truck is with a length of 13m, a height of 2m and a width of 2.5m. It is riveted with 6mm-8mm Al 5083 H321 sheet and reinforced profiles. Each vehicle uses approximately 1.8t of aluminum plates and 1.6t of aluminum profiles.

Compared with steel coal trucks, the advantages of aluminum alloy trucks are obvious. Its economic and social benefits are huge. Compared with C63 steel trucks, each truck has an increased load capacity of 19t and a 31.1% increase in transportation capacity.

The corrosion resistance of aluminum alloy coal cars is much stronger than that of steel cars, which can greatly reduce the maintenance costs of the cars. This advantage is particularly prominent when transporting coal with high sulfur content. At the same time, because the surface of the aluminum alloy is smooth, it is conducive to unloading coal.

Original Source:https://www.autoaluminumsheet.com/a/5000-and-7000-series-alloys-for-railcars.html

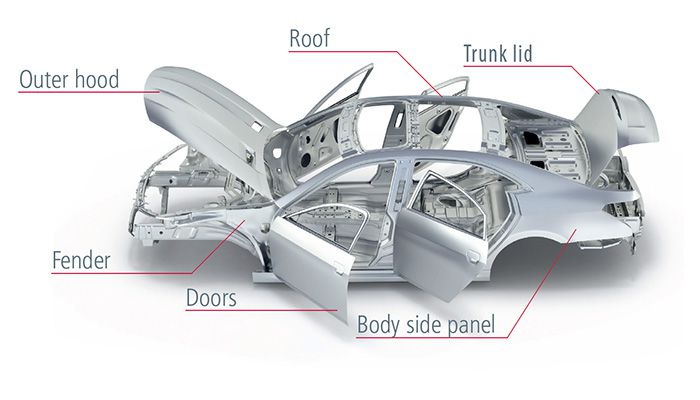

Tags: aluminium alloy used in cars ,

Prev:3003 Aluminum Strip for Battery Shell

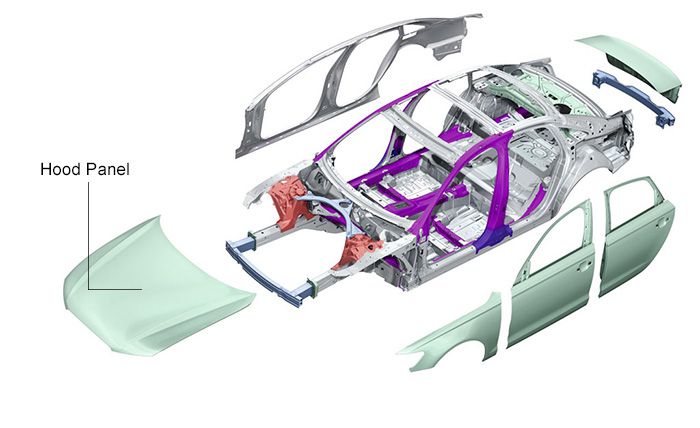

Next:6014 6056 Aluminum Sheet Metal for Cars