3003 6014 Aluminum for Automotive Manufacturing

Automotive industry aluminum is the most cost-effective top structural material for manufacturing electric cars, coupes and other products. For industrial materials, density and lightness are only one aspect.

The advantage of aluminum alloy is that its strength is relatively high, close to or exceeding that of high-quality steel. It has good plasticity, can be processed into various profiles, and has excellent electrical conductivity, thermal conductivity and corrosion resistance.

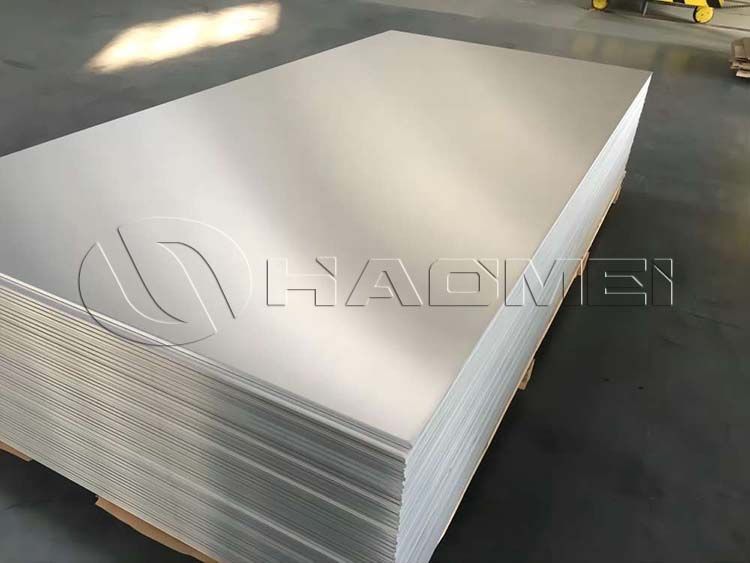

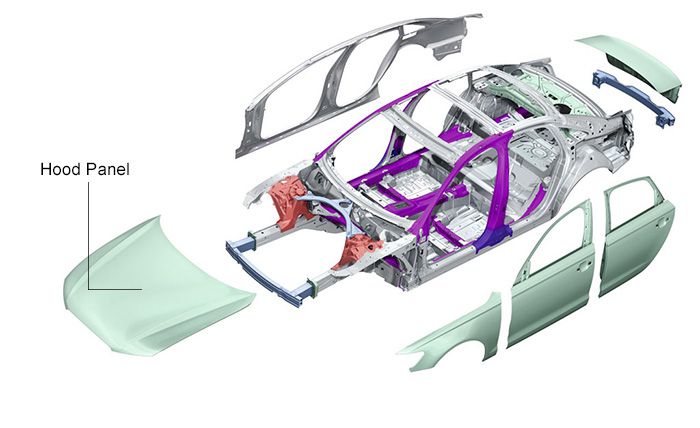

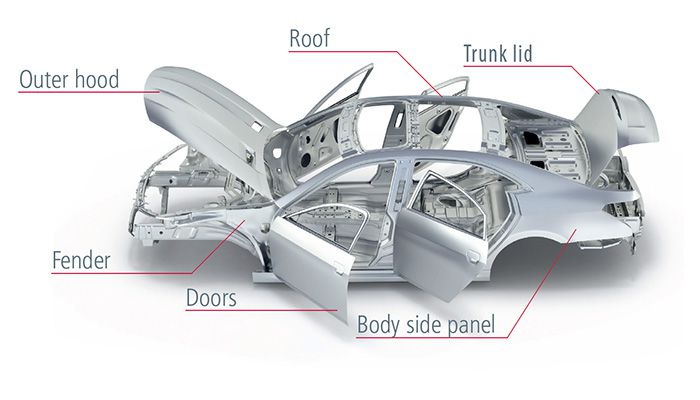

Fenders are usually installed behind the four tires of the car. The front two are fixed on the left and right lower sills, and the rear two are fixed on the rear bumper. Aluminum alloy car fenders are mainly made of 3003 aluminum alloy, which belongs to the AL-Mn series alloy. It is a widely used anti-rust aluminum. Its strength is higher than industrial pure aluminum. It has good corrosion resistance, good weldability, and poor machinability.

In order to increase the driving range, new energy electric vehicles require a large number of lithium battery combination modules. Each module is composed of several battery boxes. In this way, the weight of each battery box has a great impact on the weight of the entire battery module.

Therefore, using 3003 aluminum alloy material with low density, high strength, good stretch formability and welding performance to make battery cases has become an inevitable choice for power battery packaging.

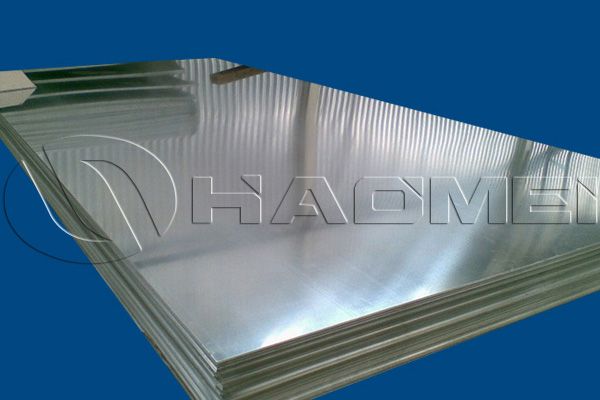

6xxx automotive aluminum alloys include 6016, 6014, 6022, etc., which are currently the main aluminum alloys used in vehicle body exterior panels. Automotive panels have high requirements on comprehensive performance, surface quality and quality stability.

The current mainstream aluminum alloy automotive sheet production process is relatively complex, including several major processes: casting, soaking, machining, hot rolling, cold rolling, and continuous heat treatment.

6014 aluminum plate is an alloy that can be strengthened by heat treatment. 6014-T651 is the main temper of 6014 alloy. Although its strength cannot be compared with 2XXX series or 7XXX series, it has many properties of magnesium and silicon alloys, including processability, excellent characteristics and electroplating properties.

It has excellent corrosion resistance, high toughness and no deformation after processing. In addition, 6014 aluminum is dense and easy to polish, and has good anodizing and coloring effect. Haomei Aluminum not only has these two car aluminum alloys, but also have the main 5xxx and 6xxx aluminum alloys. Welcome to leave message below to inquire what you need.

Original Source:https://www.autoaluminumsheet.com/a/3003-6014-aluminum-for-automotive-manufacturing.html

Tags: automotive aluminum ,

Prev:Aluminium Used in Electric Vehicles

Next:3003 Aluminum Strip for Battery Shell