Aluminum 6061 6016 for ABS Auto Body Parts

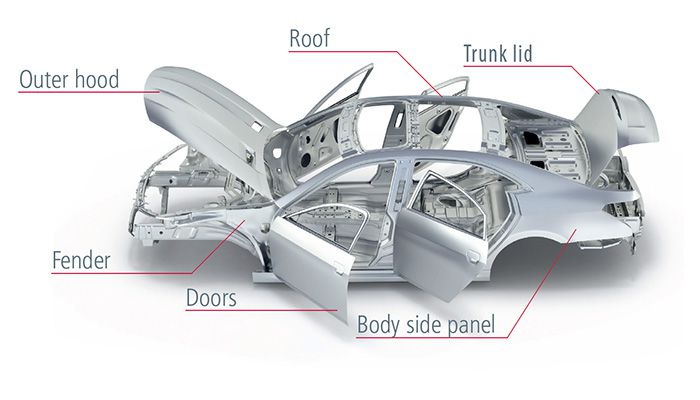

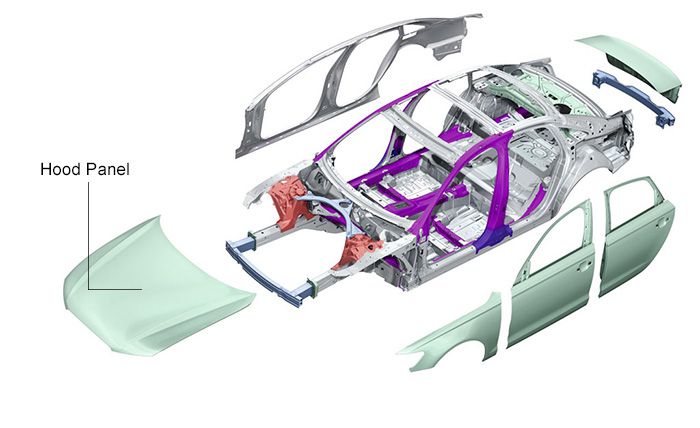

At present, the lightweight of automobiles is the most effective way to reduce the weight of itself, educe fuel consumption, and reduce emissions. Aluminum alloy has the characteristics of light weight, high strength, and corrosion resistance, so it is widely used in ABS auto body parts.

Aluminum alloys for vehicles mainly include 2xxx, 5xxx and 6xxx aluminum alloys, among which 6-series aluminum alloys are heat-treatable and strengthened aluminum alloys with high strength and are not easy to spring back after forming. And its strength and dent resistance can be enhanced in the baking stage after painting.

The United States mostly uses 6111 aluminum alloy with higher strength, while Europe tends to use 6016 aluminum alloy with better formability. The 6016 aluminum properties are very good. Its yield strength before baking is 119MPa, and can reach 218MPa after baking. The performance of Haomei 6016 aluminum sheet is basically consistent with the materials of these famous brands in the world.

6061 aluminum can reach medium strength after special treatment (T6), and its strength is higher than that of the 5 series alloys. Moderate strength is very suitable for the automotive industry. 6016 aluminum alloy can be used to make the fender, outer panel and car door of vehicles.

6xxx aluminum alloys have a higher probability of thermal cracks during welding. Common welding methods for 6xxx aluminum alloys include TIG welding, MIG welding, laser welding, friction stir welding, and CMT welding.

Cold Metal Transition (CMT)

Cold metal transition welding is a new technology improved by MIGA welding technology in recent years. The biggest difference between it and other welding methods is that cold metal transition welding realizes spatter-free welding. Cold metal transition welding coordinates the wire feeding and droplet transfer process to reduce the heat input of welding, so as to achieve the effect of spatter-free welding of thin plates below 3 mm.

Friction stir welding (FSW)

Compared with traditional welding methods, friction stir welding is an emerging solid-phase welding technology, which does not require welding materials and shielding gas before welding, and greatly reduces defects such as weldment cracks and pores during welding.

Laser Welding (LSW)

Laser welding is also one of the commonly used welding methods nowadays. The working principle is to weld the welding area of the weldment with a high-energy-density laser beam. Laser welding has the advantages of small heat-affected range, relatively concentrated heat, narrow melting zone, high weld depth-to-width ratio, small welding deformation, high welding efficiency, fine weld structure, high welding joint strength, high welding precision and reliability, and is conducive to the mass production.

Haomei Aluminum has the main 6xxx aluminum alloys like 6016 and 6061 alloy. Welcome to leave message below to inquire it.

Original Source:https://www.autoaluminumsheet.com/a/aluminum-6061-6016-for-abs-auto-body-parts.html

Tags: 6016 aluminum sheet ,

Prev:5083 5754 Auto Body Panel

Next:Is Aluminum and Aluminum Alloys are The Best Material for Car Manufacturing