Aluminum Sheet for Auto Body

ABS aluminum alloy, also known as auto body sheet, is a type of aluminum alloy specifically developed for automotive body manufacturing.

Performance requirements

Excellent formability and flange ductility: Automotive bodies and sheet metal panels are often formed by stamping, requiring ABS aluminum alloy sheet to possess excellent formability. This is demonstrated by a low yield strength ratio (the ratio of yield strength Rpo.2 to ultimate tensile strength Rm) and a high forming limit, enabling a considerable forming margin under various stamping deformation stress conditions.

Excellent surface smoothness: The surface of ABS aluminum alloy sheet after forming must be uniform in color and free of roping lines. To avoid this problem, extremely high standards are placed on the aluminum alloy's production process and quality control.

Good weldability and aging stability: Good weldability meets the requirements for direct welding of automotive components after forming. Furthermore, the aluminum sheet must also exhibit aging stability, ensuring no aging from the time it leaves the factory to the time it is stamped. Typically, the aluminum plate is required to be aging-free for six months.

Excellent bake hardening properties: Automotive lightweight requires aluminum sheet to possess high bake hardening properties. This means that after stamping, deformation, and paint baking, the sheet metal's yield strength significantly increases, ensuring the finished sheet metal parts have high dent and compression resistance.

Strong dent resistance: The ability of automotive aluminium and sheet metal parts to resist external forces and intrusion from foreign objects without denting or permanent deformation is known as dent resistance.

Excellent Zr/Ti salt chemical conversion performance: Before applying lubricant, ABS aluminum alloy requires a surface passivation treatment to form a Zr/Ti salt conversion film, creating a good base for lubricant adsorption.

ABS aluminum alloys

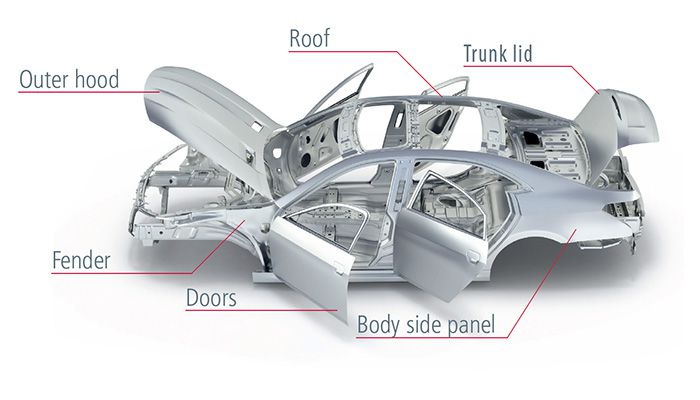

5182 aluminum: 5182 alloy is commonly used in automotive interiors, doors, hoods, and front and rear fenders. Doors, for example, place high demands on sheet strength, formability, and corrosion resistance, and 5182 aluminum alloy sheet effectively meets these requirements.

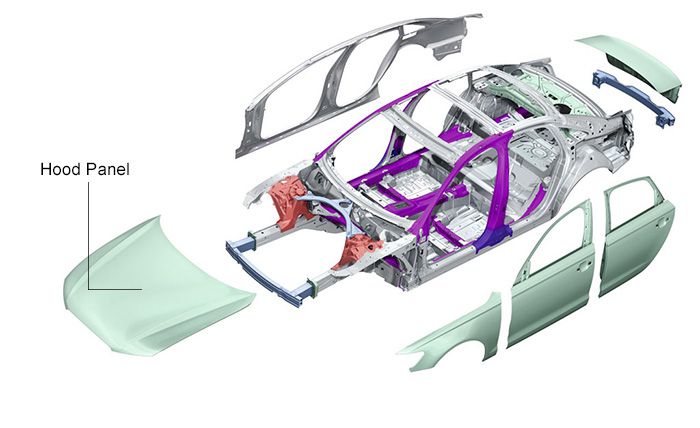

6016, 6111 and 6061 aluminum: 6111 and 6016 aluminum sheets are commonly used in automotive hood panels, not only enhancing the vehicle's aesthetics and aerodynamics, but also ensuring lightweight, safety, and manufacturing feasibility.

6061 is commonly used as a raw material for automotive underbody protection, wheels, and hoods. In automotive wheel manufacturing, 6061 alloy's moderate strength and excellent processing properties enable it to meet the requirements for withstanding vehicle weight and impact forces during driving, while also facilitating processing into a variety of complex wheel shapes. Haomei Aluminum is one of the ABS aluminum suppliers. Welcome to contact us for more information.

Original Source:https://www.autoaluminumsheet.com/a/aluminum-sheet-for-auto-body.html

Tags: 6016 aluminum sheet ,

Prev:What Are 3003 Aluminum Applications

Next:What Are Metals Used in Cars