6016 T4 Aluminum

What 6016-T4 is used for, and why it is specified

6016 T4 aluminum is a heat treatable Al Mg Si alloy widely selected for outer and inner automotive skins where high formability, consistent surface appearance, and paint bake performance are required. In T4, the material is solution heat treated and naturally aged, which supports stable stamping behavior during storage and transport, while still retaining the ability to gain strength during the OEM paint bake cycle.

For purchasing teams and processors, the practical value is that it can be formed into complex panels with low risk of tearing, then achieve higher in service strength after paint baking. This is one reason 6016 is frequently compared with adjacent grades in the same family, especially when balancing dent resistance, hemming, and surface critical requirements. If you are aligning specifications across multiple platforms, it helps to understand where it sits within the broader 6xxx alloys.

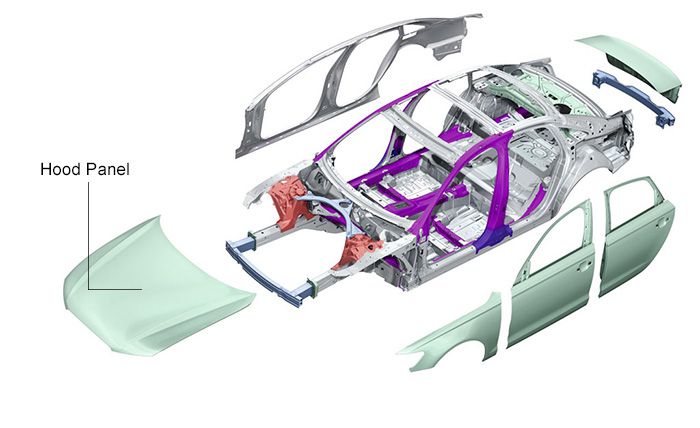

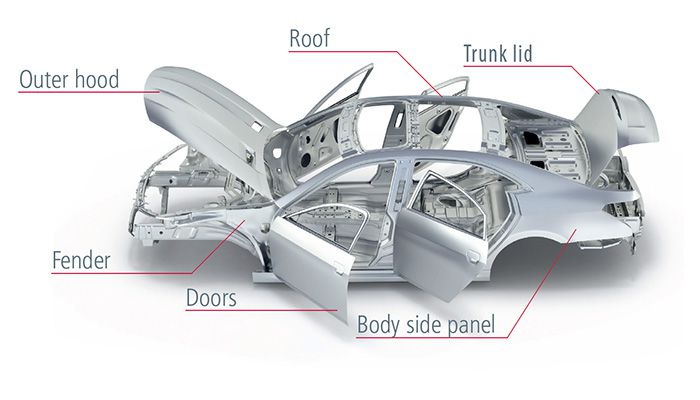

Typical applications

Outer panels such as doors, fenders, hoods, and decklids where surface appearance matters.

Inner panels and reinforcements requiring reliable forming and stable springback control.

Parts that benefit from bake hardening to improve dent resistance after painting.

Performance profile that matters in mass production

When sourcing material for high volume stamping, buyers usually focus on a short list of production risks: split rate, springback, surface defects, and coil to coil consistency. 6016-T4 is commonly specified because it addresses these points in a balanced way.

Formability and hemming behavior

T4 temper supports deep draw and stretch forming, and it is often chosen for outer panel designs that require tight radii or hemming operations. Actual hemming success depends on gauge, tooling, lubrication, and surface condition, so material supply should be consistent in yield behavior and surface roughness. In practice, many plants prefer controlled surface texture and stable mechanical properties to keep forming windows predictable.

Bake hardening response

A key reason automotive OEMs like this grade is its ability to increase strength during the paint bake cycle. Rather than relying only on as delivered strength, the final part benefits from bake induced strengthening, improving dent resistance without sacrificing initial formability.

Surface and appearance

For outer panels, surface quality is often the true cost driver. Expectations typically include:

Low defect rates for inclusion, slivers, roll marks, and chatter.

Tight control of surface roughness for paint appearance and forming lubrication.

Uniform color and reflectivity after pretreatment and painting.

Corrosion performance and joining

As with other Al Mg Si alloys, corrosion behavior is influenced by pretreatment, coating systems, and joining choices. For assembly lines, compatibility with resistance spot welding, adhesive bonding, and mechanical fastening is usually evaluated as part of the OEM or Tier 1 qualification. If the program specifically targets car body applications, the product page for 6016 Aluminium Alloy for Car Body can be a relevant reference for typical supply scope.

Supply formats, specifications, and purchasing checklist

Bulk procurement success is typically determined by how well the supply matches plant realities: blanking efficiency, stamping stability, and logistics. Below is a practical checklist for specifying 6016-T4.

Common supply options

Form: sheet or coil supply depending on blanking and press line setup.

Thickness range: often ordered in body panel gauges, with tighter tolerances for outer skins.

Width and length: tailored to blank nesting and scrap rate targets.

Surface: mill finish or pretreated requirements depending on your process route.

Typical ordering parameters to confirm

| Item | What to specify | Why it matters in production |

|---|---|---|

| Temper | T4 | Controls forming stability and aging behavior |

| Thickness tolerance | Program specific | Influences dent resistance, mass, and die tuning |

| Flatness and residual stress | Defined limits | Reduces coil set, waviness, and stamping instability |

| Surface class | Outer vs inner panel level | Paint appearance and defect yield |

| Oiling | Type and amount | Impacts friction window and cleanliness |

| Mechanical properties | Target range, not only minimum | Controls springback and tool compensation |

| Coil ID, OD, weight | Line capability | Prevents downtime and handling risk |

Quality documentation often requested

Depending on the automotive program, bulk orders commonly include mill test certificates, inspection reports for surface and dimensional metrics, and traceability data. Many customers also request process capability data for thickness and mechanical properties to ensure coil to coil consistency.

Practical selection notes vs nearby grades

If your program compares multiple alloys, the decision often comes down to surface criticality and forming margin versus final strength targets. 6016-T4 is frequently selected for outer panels because it offers an attractive combination of forming ease and post bake strengthening, while keeping surface requirements achievable at scale.

What to share when requesting a quotation

To speed up technical alignment and avoid revision cycles, prepare:

End use: outer or inner panel, with part name and forming process.

Gauge, width, length or coil width, and annual tonnage.

Surface class expectations and defect criteria.

Preferred lubrication, packaging, and coil weight limits.

Any required standards or OEM specific requirements for testing and documentation.

This approach typically results in faster matching of rolling schedule, surface route, and inspection plan, helping you secure stable supply for serial production.

Original Source:https://www.autoaluminumsheet.com/a/6016-t4-aluminum.html

Tags: 6016 T4 aluminum , automotive aluminum sheet ,

Prev:6016 T6 Aluminum